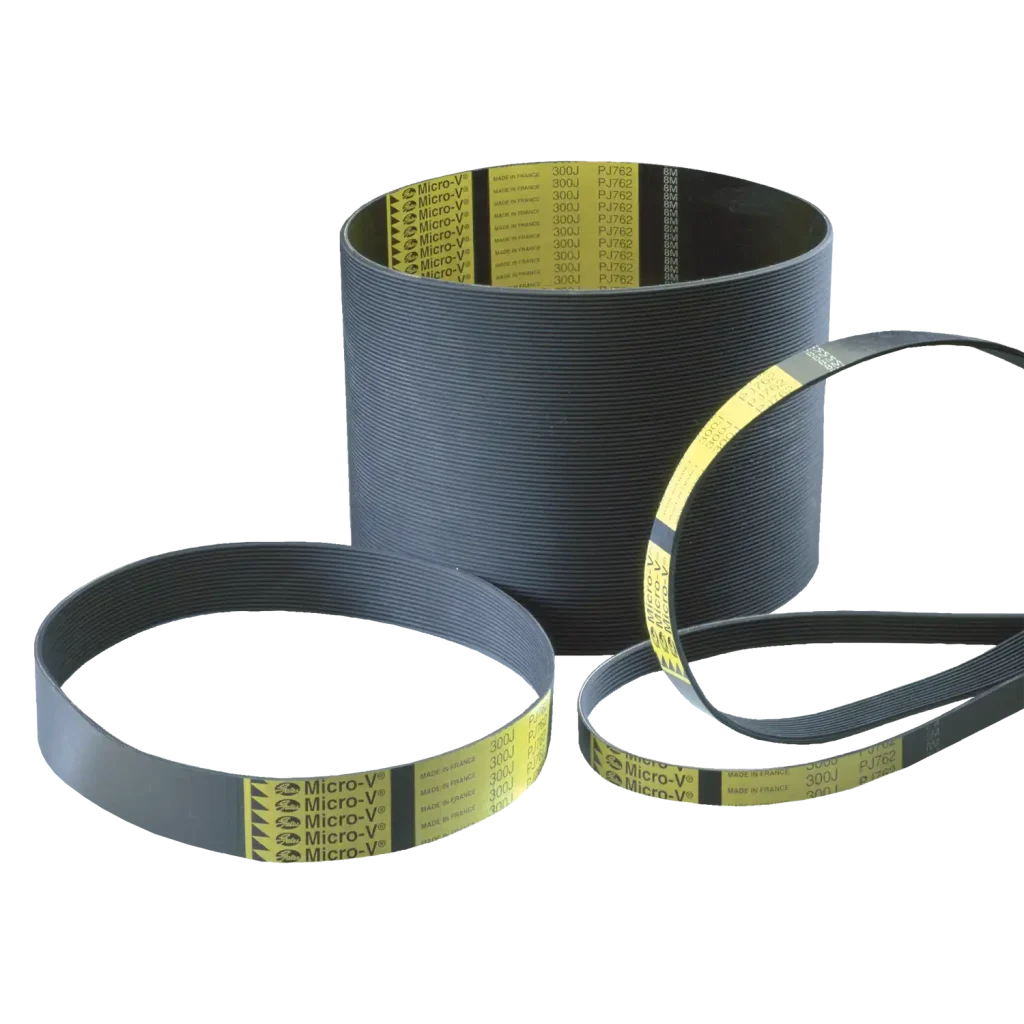

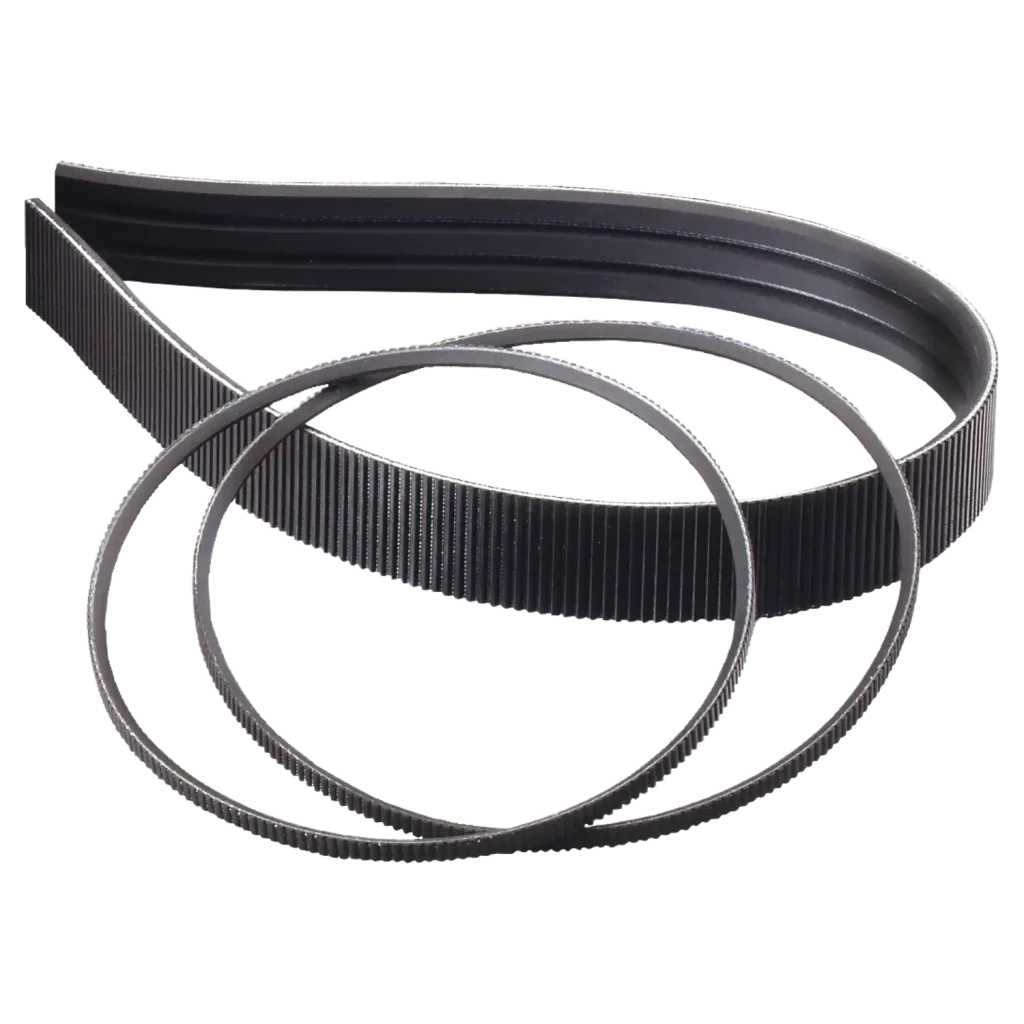

Transmission belts and belting have two main models, each with specific characteristics for different types of applications: friction drive belts, where contact is generated between the pulley and the belt to transfer friction and generate movement, ideal for systems that require a certain level of flexibility; and timing belts for synchronous transmission, which have teeth on the inside surface that match the timing pulleys, allowing for precise transmission. The latter type of belt and drive belt is perfect for applications that require precise synchronization.

Transmission belts and belting

Sectors

Heavy and industrial vehicles

Transmission belts and belting

- Drive belts with protective lining

- Die-cut straps with open sides

- High wear resistant belts for dusty environments

- Multi-channel transmission belts

- PU timing belts with parabolic profile and carbon fiber ropes

- PU and rubber timing belts of different profiles

- Meter timing belts with accessories and covers

- Customized timing belts, welded or continuous corded

- Industrial conveyor belts with coverings and profiles

Find out what Adalis can do for you

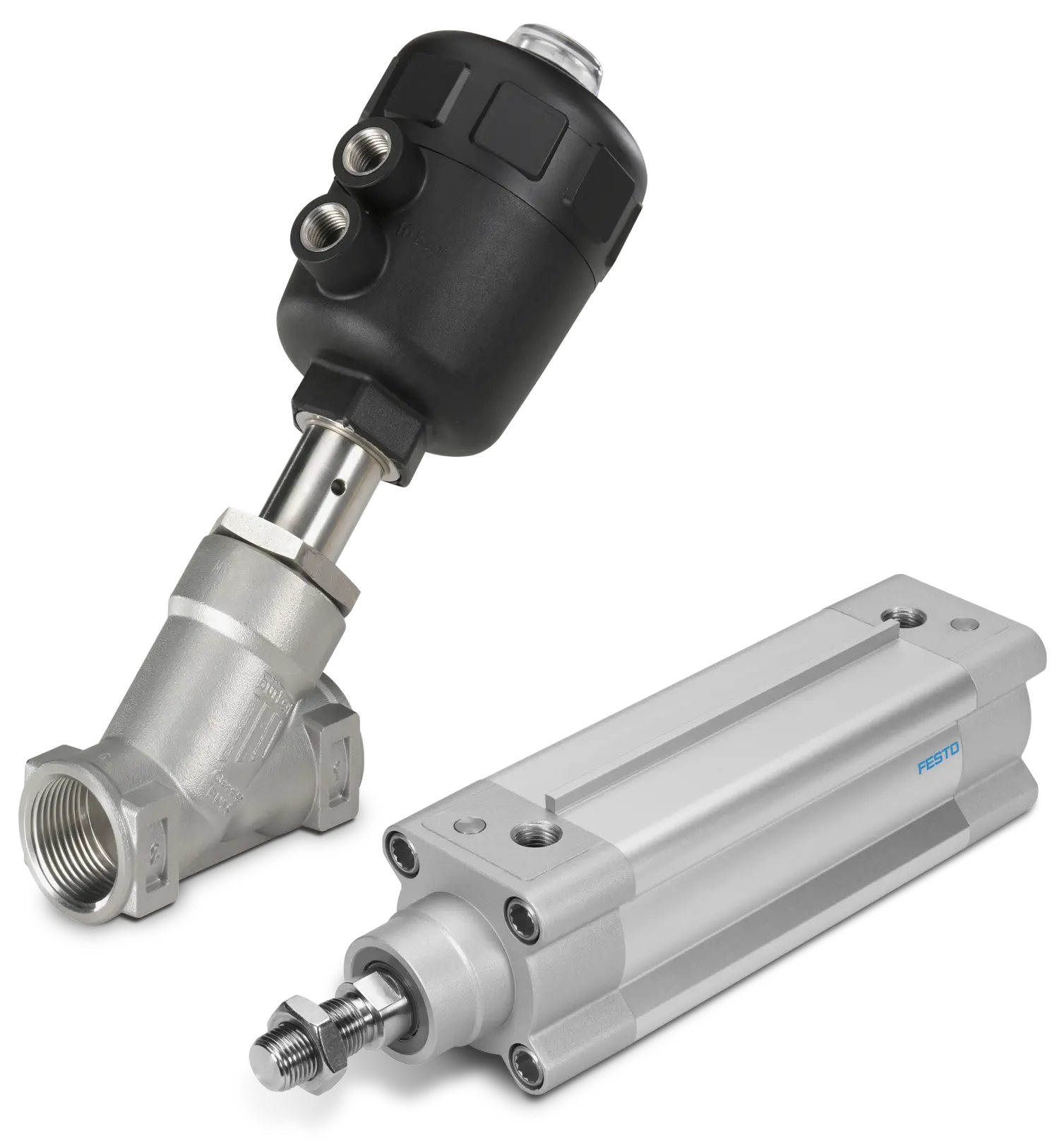

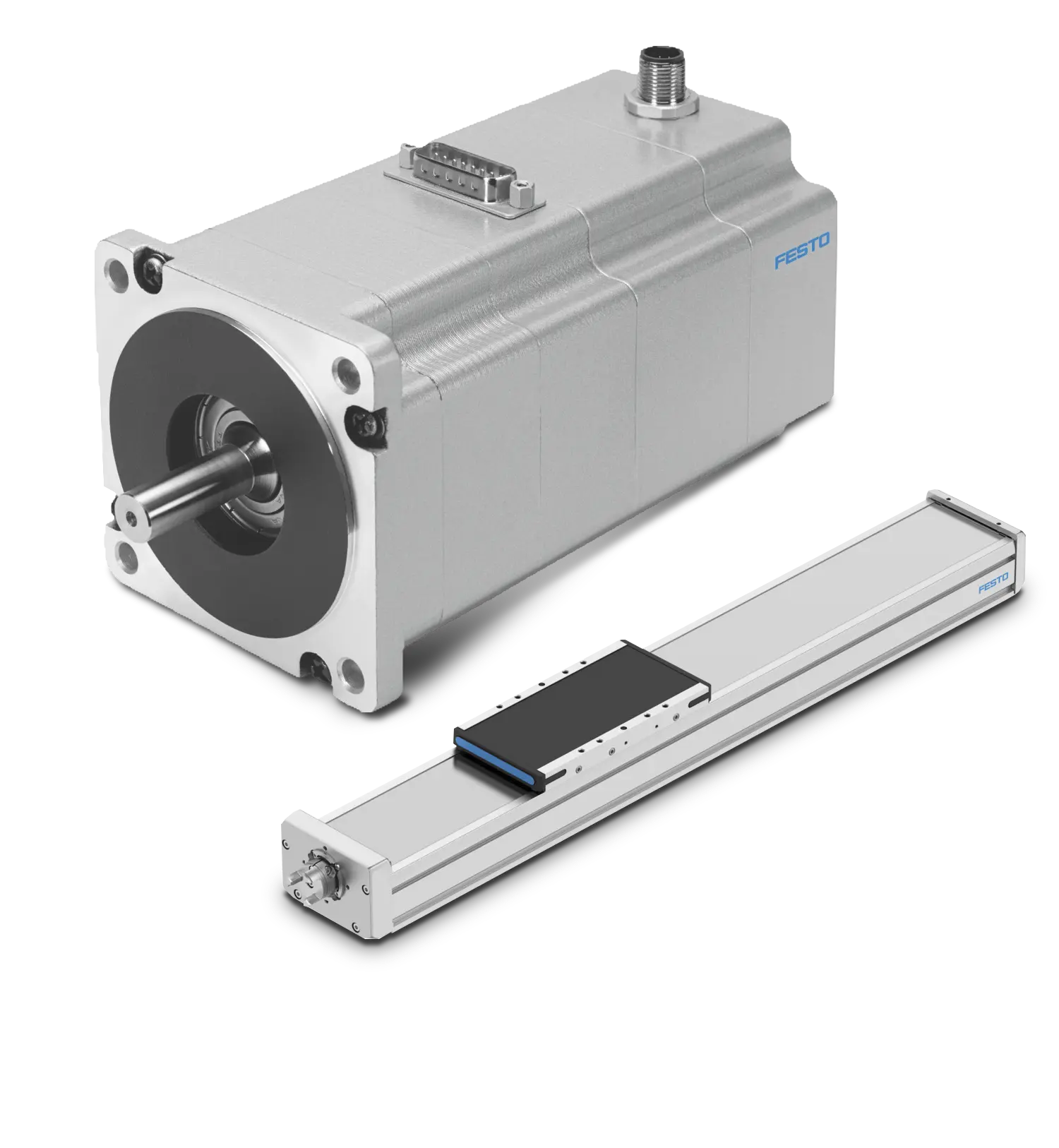

In Adalis we want to offer you a complete service, therefore, we only count on quality brands that can guarantee the reliability of each of its components. Thanks to our experience, we provide each customer with an accurate advice service for the selection of the components of their equipment.

Consult our specialist

"*" señala los campos obligatorios