In this article, we present the range of mini rigid couplings Ruland for precision motion control applications. We will detail functionality, types and assembly.

Historically, couplings have been imprecise, inexpensive and often homemade components for simple shaft-to-shaft connections.

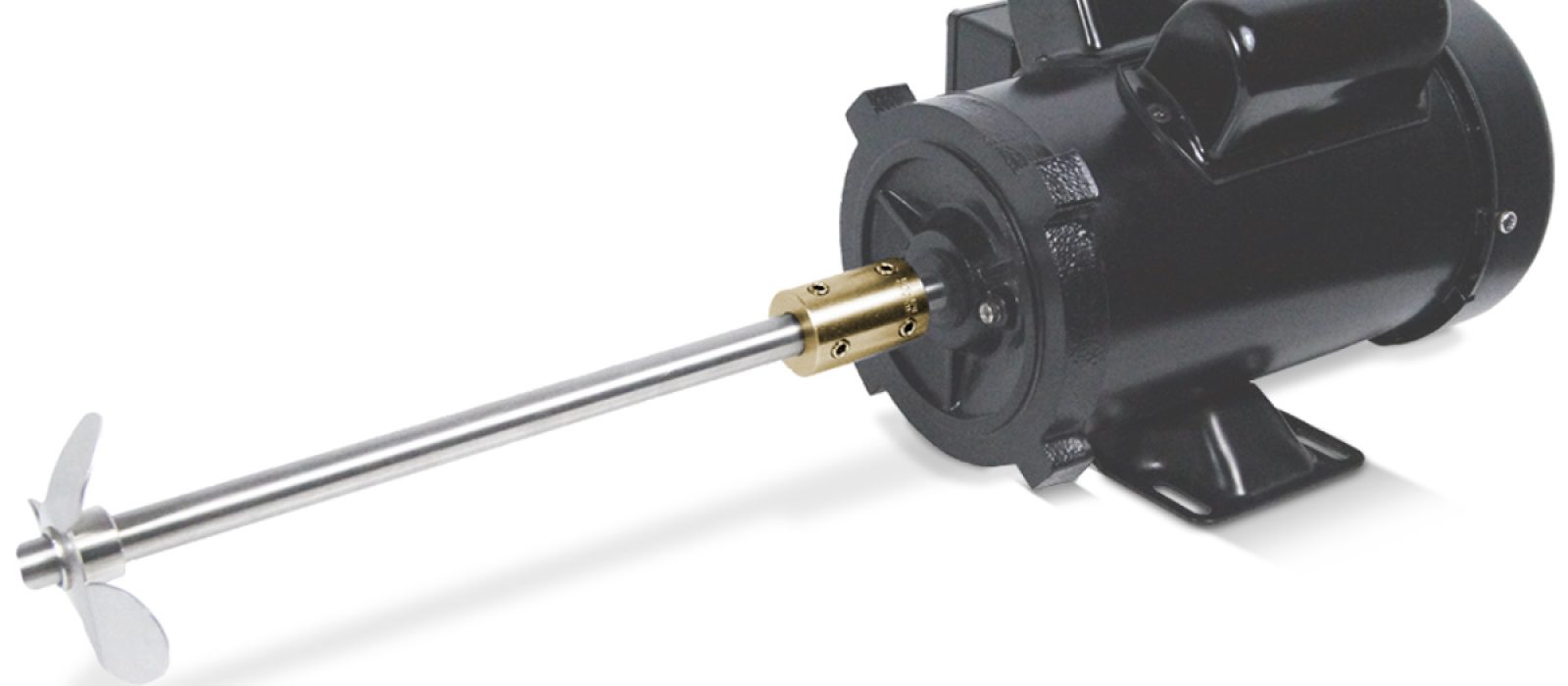

In contrast, today, even smaller rigid couplings are increasingly used in motion control applications due to their high torque capacity, rigidity and zero backlash, especially those made of aluminum.

Rigid couplings do not operate at high revolutions (rpm), because they cannot compensate for the thermal changes in the shafts caused by the high speed. However, they do serve for low rpm applications, where Ruland couplings offer excellent performance.

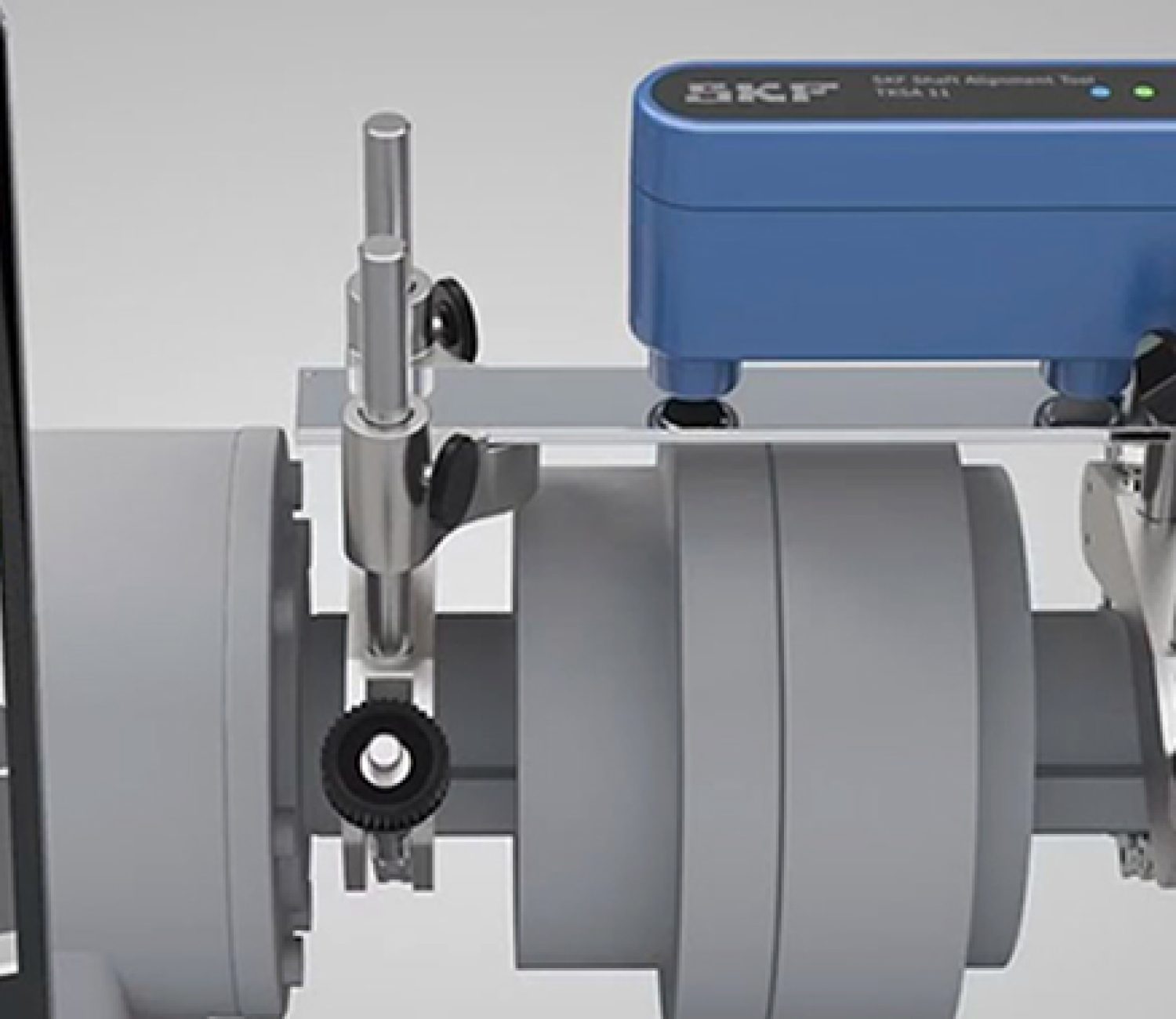

In addition, they serve to establish the shaft alignment in misaligned systems.

Which rigid coupling model to choose?

Ruland guarantees that the size and geometry of its couplings are appropriate. The hubs are ground in order to ensure correct collinearity. This ensures maximum shaft contact and greater torque transmission capacity. Three Ruland rigid coupling models are available:

1) Set Crew.- The basic form has set screws that hold the coupling to the shaft.. They are less used because any adjustment of the screw can cause damage to the shaft. As an advantage, they are more economical.

2) One- Piece.- A superior alternative is the one-piece rigid clamp-style couplings. They are coupled to the shaft to provide high torsional holding power without damaging the shaft.

3) Two-piece.- The two-piece rigid clamp-style coupling, allows disassembly and maintenance, without the need to remove all components.

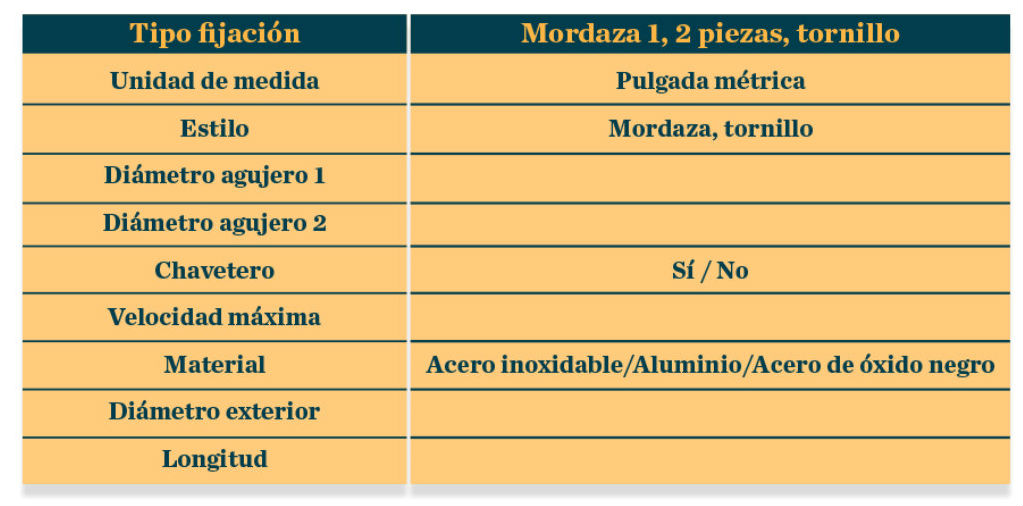

On the Ruland website there is a selector where you can filter your search according to certain criteria:

Installation of rigid couplings

Most of Ruland's rigid clamp-type couplings are designed with the bolts close together and arranged in pairs. Combined with a cross-section, this design facilitates a higher retention capacity and also accommodates slight deviations in the size of the two connected shafts.

We recommend installing these couplings by tightening the paired bolts alternately, in several steps. This way we guarantee a correct torque in all of them, by distributing the tightening tension more evenly in all of them.

All this allows more precise fit and clamping power.

Epidor is the official distributor of Ruland in Spain and Portugal. To see the rest of Epidor's power transmission range click here. here.