Loctite adhesives and their effectiveness are already a solution we all rely on to create strong assemblies, but what if I told you there was a way to maximize their effectiveness while saving on product? Let's talk about LOCTITE reservoirs and dispensers and how this product can offer you the integral solution to all your applications and assemblies in your industry.

When we talk about LOCTITE brand dispensing equipment, we are referring to new generation solutions which allow precise dispensing of these instant adhesives in virtually any assembly process: from benchtop applications to fully automated production lines.

LOCTITE integrated tanks and dispensers, with their integrated adhesive dispensing design, meet the increasingly complex needs of manufacturing by offering a number of important advantages:

- Increases productivityThe semi-automated processes can be converted into fully automated ones.

- Improved accuracy and reliabilityThey allow more precise and controlled dispensing of a wide range of LOCTITE adhesives.

- Simplify design and allow for integration with other LOCTITE equipment, with the range of adhesives and with the assembly and fabrication of all types of applications.

- They are more sustainableThe right amount is used in each process and no product is wasted.

- Decreases the cost of the adhesives.

LOCTITE dispensing equipment for all your applications

Although the LOCTITE container is designed for easy and accurate dosing, in some cases it may be necessary to applying the product in a more millimetric mannerwithout wasting a drop; using the right quantities and thus achieving greater sustainability.

There are several integrated LOCTITE dispensing equipment capable of applying adhesives with more precise determinationmanually or automatically.

At ADALIS we are experts in industrial suppliesTherefore, we present you 3 dosing equipments according to the needs to be met:

Digital Syringe Dispenser

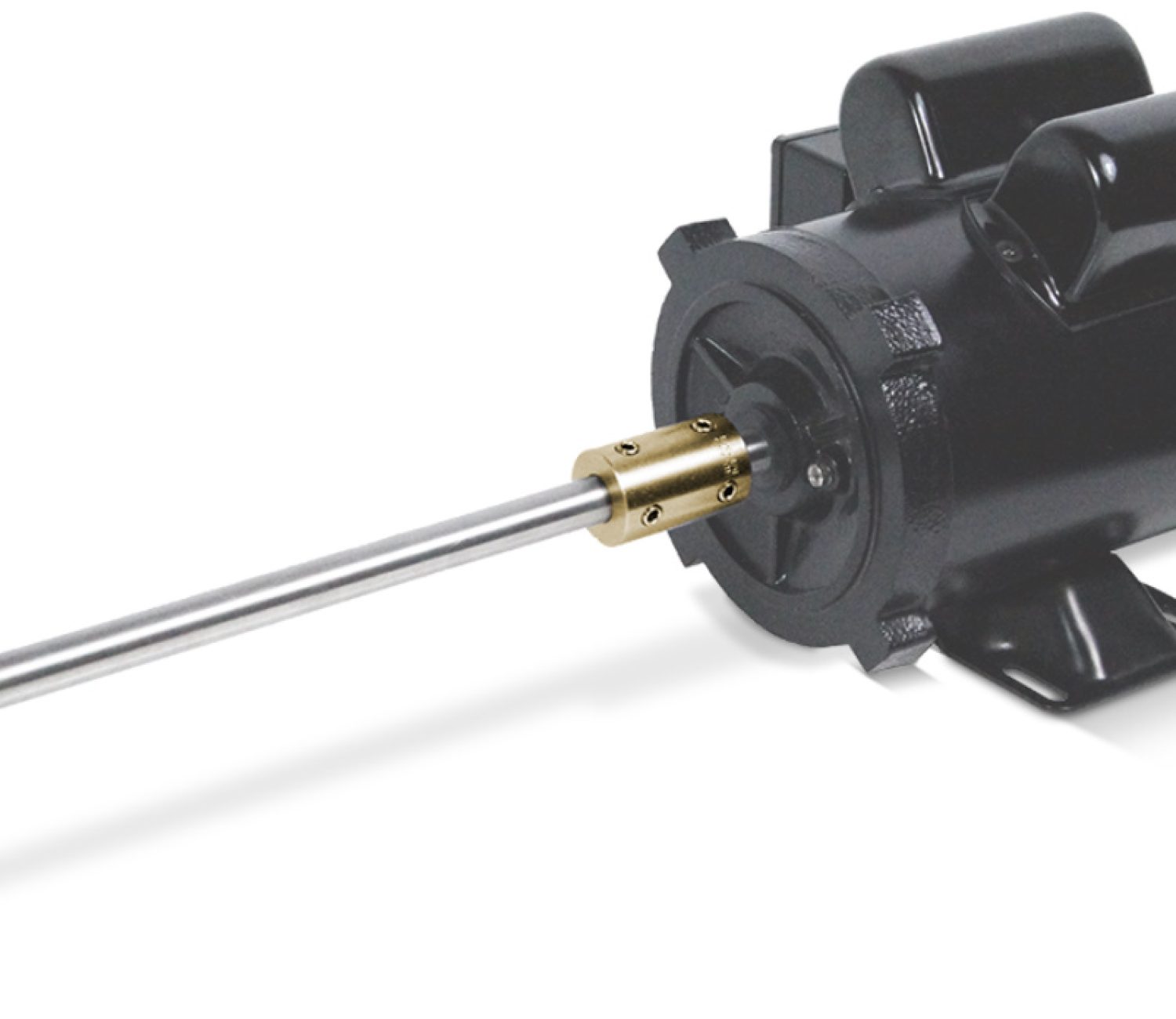

The LOCTITE syringe and cartridge dispensing system is a electro-pneumatic dosing system which has been designed exclusively for the application of adhesives and sealants in 10 ml, 30 ml, 55 ml and 300 ml syringes and cartridges; and for viscosities from high to low.

This syringe dispensing system offers three models of operation (manual, incremental and timed) and includes application needles, syringe, syringe adapter, syringe holder and foot switch.

Easy to use and integrate with other equipment, this LOCTITE syringe and cartridge dispensing system offers the possibility of rejection, eliminating dripping and stringing.

Integrated Digital Peristaltic Dispenser PU20

The LOCTITE PU20 digital peristaltic dosing system is designed as a the best dosing option for single-component and low-viscosity products.

One of the advantages of this dosing equipment is that it allows the adhesive to be applied directly from the product packagingThe airless, air-entraining system prevents premature clogging and curing of moisture-sensitive adhesives, such as cyanoacrylate adhesives. In addition, this model featuresn a digital speed controlThis allows for improved accuracy and repeatability. Perfect for use in manual, benchtop or semi-automatic processes.

Integrated Dispenser Pulse RC50 I4.0

This LOCTITE integrated dosing equipment is compatible with 250 ml, 200 g, 500 g, 1 L and 2 kg containers and combines a reservoir and controller, which provides two output channels that allow two pneumatic outputs to be controlled. With a precision digital pressure regulatorIt allows a pressure of up to 100 PSI (7 bar) and has a safety depressurization valve.

Indicated for use with adhesive technologies such as anaerobics, cyanoacrylates, UV and visible light curing adhesives, it is also suitable for low viscosity products. It has 3 operating modes for manual, semi-automatic or fully automatic processes and features a user-friendly touch screen. In addition, it can be connected via Wifi, Ethernet and Bluetooth.

Consultation with our ADALIS technical department to know why you need LOCTITE® dosing equipmentThe most suitable model for your work processes and the possibilities of adapting it to your application.