As a leading brand in the field of tools for surface treatment and cutting of materialsPFERD has been with us for a long time. Working with first-class suppliers gives us the security of offering our customers the best solutions on the market.

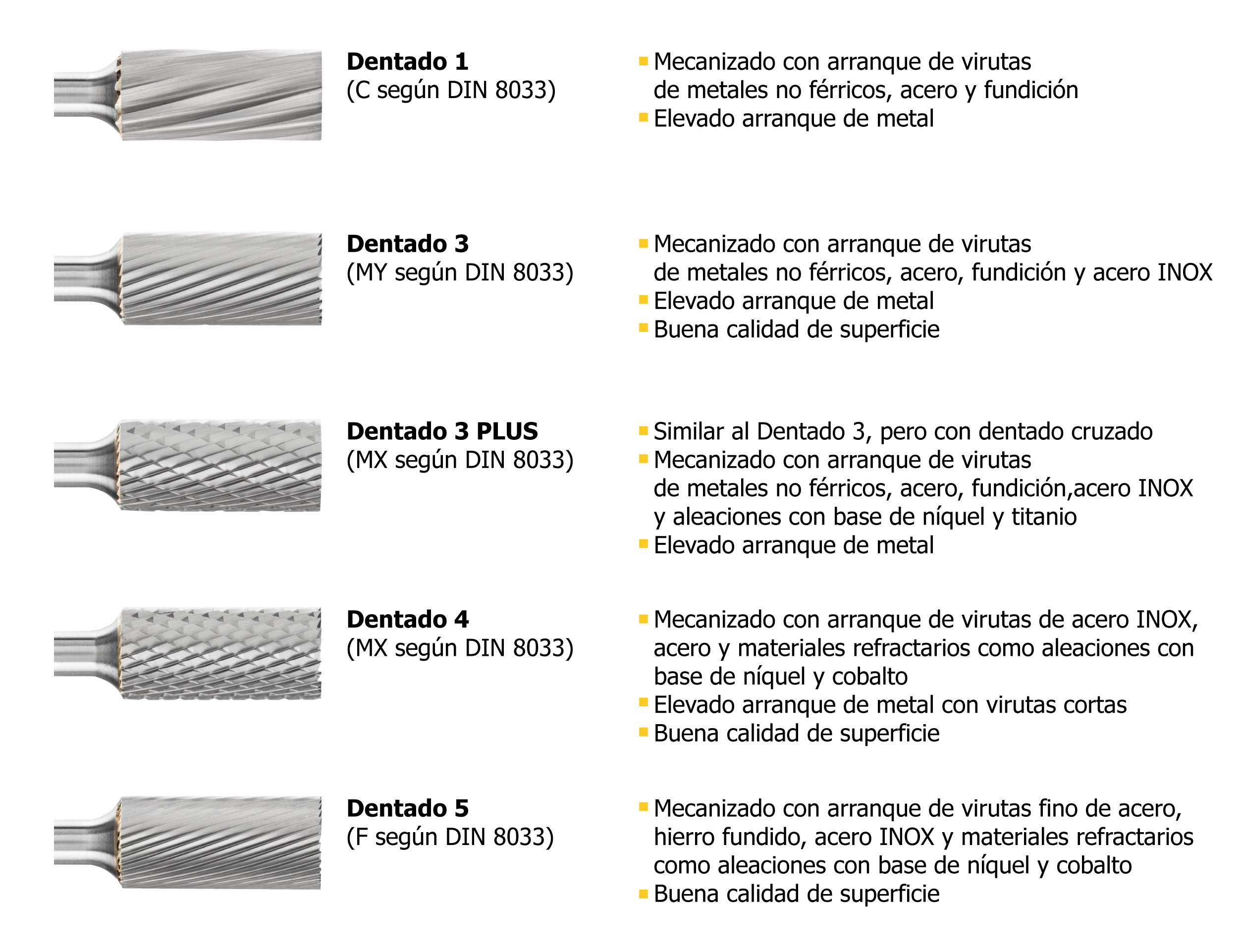

Today we are going to dedicate this space to the carbide burs of this company that has been proposing for more than 200 years the following products high performance tools. But first let us remember what the standard toothing for universal applications are; doing so will help us to understand the high cost-effectiveness of PFERD tools when compared to other milling cutters with conventional toothing.

It should not be forgotten that, apart from the toothing, the shape in which they are designed influences the choice of the right milling cutter. There are many types of milling cutter shapes, from the traditional cylindrical shape to the 90° pointed conical shape, and their application will depend on the work to be done.

Tungsten carbide burr types for high-performance applications from PFERD

The brand has developed a wide range of proposals designed and built to meet the requirements of the different materials on which each tool must operate. In short, PFERD "has developed specific toothing systems for various materials" and this effort has led them to become the main protagonist of our milling tool catalog.

At ADALIS you will find a wide range of carbide end mills from PFERD. The company's proven track record in the sector allows it to have first-hand knowledge of the different needs that an operator in the field may require.

The versatility of ALLROUND toothing

This toothing guarantees outstanding grinding performance and very high stock removal on the following materials: non-ferrous metals, cast iron, INOX steel, steel and cast steel.

The aggressiveness and guideability of STEEL teeth

The brand has developed these milling cutters for steel machining and cast steel in particular. They stand out for their high profitability and agility; in addition, their material removal capacity is very high.

One more 100% start-up with INOX toothing

With the design of this geometric milling cutter made of stainless steel, the brand has succeeded in proposing a perfect tool for machining precisely in this material.

PFERD perfects the ALU toothing system

This toothing is specifically designed for chip removal on aluminum. This tool is particularly suitable for cutting aluminum chips and is very smooth running during use.

NON-FERROUS teeth

This tool has been developed to remove chips from non-ferrous metals and fiber-reinforced plastics. It is highly efficient and precise.

Cast iron teeth CAST

This is a relentless and extremely valuable tool for foundry machining tasks. Very aggressive in chip removal (large chips), it allows a good chip removal.

The high performance of TITANIUM® gearing

This toothing responds to the need to operate with a special milling cutter when working with hard titanium materials, which are complex to machine. We highlight its exceptional grinding performance.

Tungsten carbide burs with PLAST® cutters

These milling cutters are a perfect choice for tasks that involve working with the contours of GRP and CFRP with a fiber content ≤ 40%. As a curiosity it is interesting to know that this tool is highly valued in the robotic construction sector.

FVK and FVKS toothing

Both types of toothing have been developed for working with GRP and CFRP with a fiber content > 40%. These soft tools guarantee a smooth cutting edge.

Of course, all the milling tools we offer ensure operator comfort by reducing both vibrations and noise pollution.

In addition, ADALIS can advise you on what type of carbide burs may be more suitable for your work. Contact us at without commitment.