Have you ever wondered what is a hydraulic turbine and what is it used for?? In this publication we want to explain it to you and put an end to all those doubts that may arise. Here we go!

What is a hydraulic turbine?

The hydraulic turbine was invented in 1827 by the Frenchman Benoî Fourneyron.

It is about a machine that uses the energy of motion of a fluid passing through it, generating a rotary motion. Thanks to this, it transports the energy and motion to a machine or generator by transferring it to the shaft. At this point, the following is achieved transforming mechanical energy into electrical energy.

What it is used for

To understand what the hydraulic turbine is used for, we have to talk about hydropower.

It is the energy that is produced by harnessing the potential and kinetic energy of water.in waterfalls or the sea. In order to use it, it is transformed to different levels.

The energy of rivers has been used by humans for many years, and, at present, hydropower is one of the proposed renewable energy sources. that is gaining the most weight.

- Normally, we find hydroelectric power plants in locations where rainfall and geographic differences in elevation facilitate the construction of dams and the creation of energy.. Thanks to these slopes, kinetic and potential energy is generated from the mass of water. In its fall, the water must pass through a hydraulic turbine, which is used to transmit the energy to a generator that converts it into electricity.

- Also is achieved through the conduction of water from a stream to a closed pipe where the turbine is located.. The water is eventually collected in a dam and, thanks to changes in elevation, energy is generated.

- In other cases, a dam is built to divert part of the river's flow. and thus gain a few kilometers of level in the riverbed.

In all of the above cases, the turbine remains connected to a generator that produces electricity. Each hydroelectric power plant may have several hydro turbines installed.

The function of a hydraulic turbine is to generate, from the energy of the fluid, which passes through it to generate rotational energy. Thus, from dynamic energy to electrical energy and does so thanks to the generator that transforms this energy.

Hydraulic turbine models

All hydraulic turbines have a water inlet channel, an internal system of blades and impellers on which the water impingesThe water is then discharged through the pipes by rotating the shaft connected to the generator.

We differentiate three types of hydraulic turbines depending on the arrangement of the shaft, the blades or the position of the same with respect to the water inlet. They are the Pelton, Francis and Kaplan. Below, we explain them to you.

Types of hydraulic turbines

Pelton

It is characterized by having a cross flow of water and partial admission. It is considered the evolution of the old water mills, that is why its blades are called spoons. It is ideal for working with large waterfalls of more than 200 meters but with low flow. The impact of the water on the impellers is responsible for the shaft rotation.

Francis

It is of the most used is, therefore, a suitable for medium height jumps of 10 to 200 meters. standing out for its versatility. The water enters perpendicular to the turbine shaft and internally has a set of guide vanes, called distributor, which modifies its position, we can make the turbine work with different water flow rates and pressures.

Francis hydro turbines are of mixed and reaction type. There are many types of Francis hydro turbines, some of some complexity that are capable of varying the angle of the blades during operation.

Kaplan

In Kaplan hydraulic turbines, the water reaches the feed zone and is distributed through the nozzles where, before exiting, it hits the blades or vanes located in the lower part of the assembly, causing the shaft to rotate and the shaft rotates the generator.

Kaplan turbines are characterized by being axial, i.e., they are able to regulate and adapt the angle of their blades while performing their function. They are specifically designed to work with large quantities of water or with small waterfalls (up to 50 meters).

Since the end of the 1980s, in ADALIS we have collaborated with power companies and the main engineering firms in the sector. in the introduction of lubrication-free friction elements for the modernization of hydraulic turbines located in the Iberian Peninsula.

As a business group, we are focused on rowing towards a more sustainable world.. Therefore, we are aligned to row towards renewable energies and comply with Sustainability Goal number 7 of the 2030 agenda.

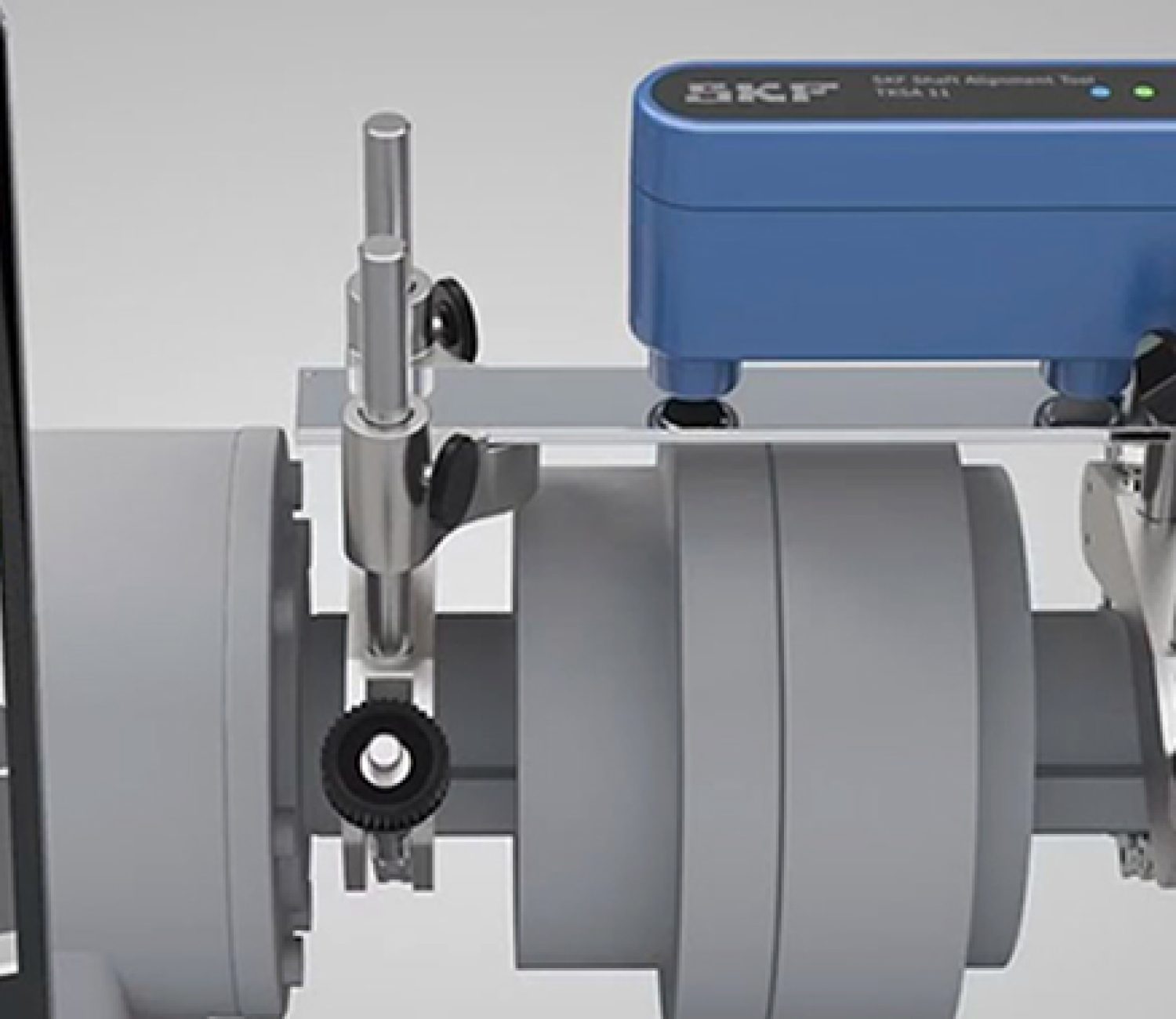

With the close collaboration of our strategic supplier, TENNECO-DEVA we have introduced a full range of high-tech, high-performance self-lubricating products which have helped to improve the productivity and longevity of the hydraulic turbines in which they have been applied.

Our grain of sand

ADALIS Industrial Solutions has been involved in most of the modernizations in which lubrication has been eliminated over the last 40 years.. Thanks to this breakthrough, the danger of lubricant contamination of rivers is eliminated, a further step towards achieving the goal of sustainability the 2030 agenda.

In Spain, the most commonly used turbine is the Francis in its vertical version. The main points of application are the guide vanes, which serve for regulate the flow rate of water entering the impeller. In this case, we have developed axial bushings and washers; the distributor ring, on which the blades are mounted and which allows varying the direction of water flow, and for which it has been necessary to mount radial and axial sectors. Finally, they are also applied to the connecting rods and connecting rods that act as mechanical fuses in the system. For this last case we have mounted axial bushings and washers.

For proper operation, it is essential that, in all installations, there be control valves to regulate water inlet and outlet.. Self-lubricating elements in the form of axial bushings and washers are also mounted on the shafts of this equipment.

In addition, we also we have participated in modernizations of Kaplan and Pelton turbines.However, due to their configuration, they do not have as many oscillation points and therefore fewer applications of self-lubricating elements.

If you need us to answer any questions about this blog post, please contact us at contact with us.