Bearing wear is a delicate subject that is often difficult to predict, even using observation and monitoring methods. Today we would like to share with you the studies carried out by SKFthe world's most prestigious manufacturer.

Bearing wear can occur for one or more reasons. The most common are inadequate lubrication (due to lack of lubrication or the use of lubricants unsuitable for the application), contamination and shaft misalignment. This wear can cause the bearing to malfunction or even be completely destroyed.

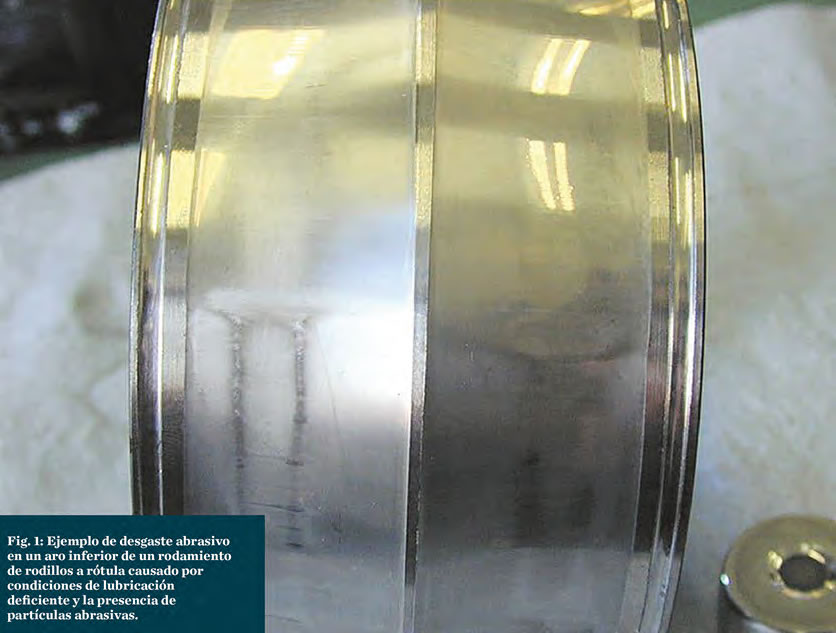

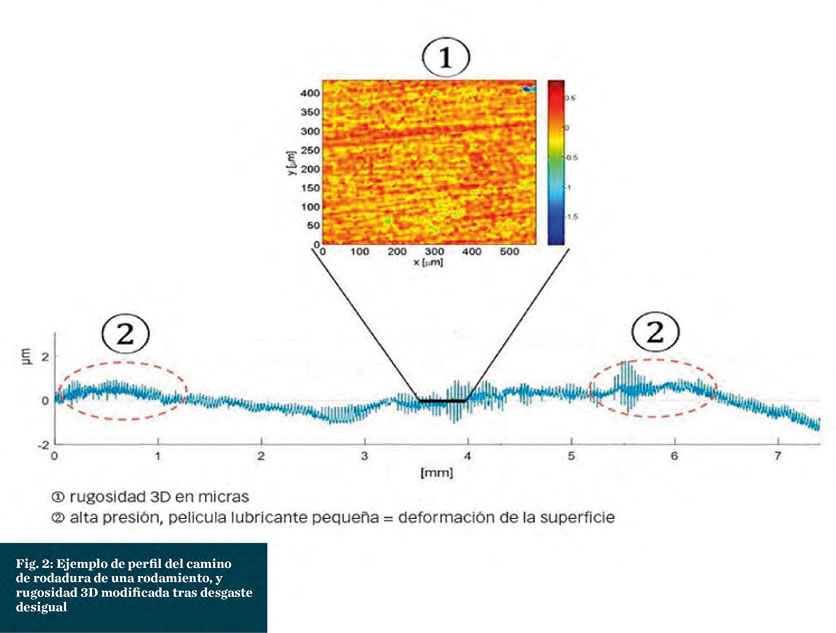

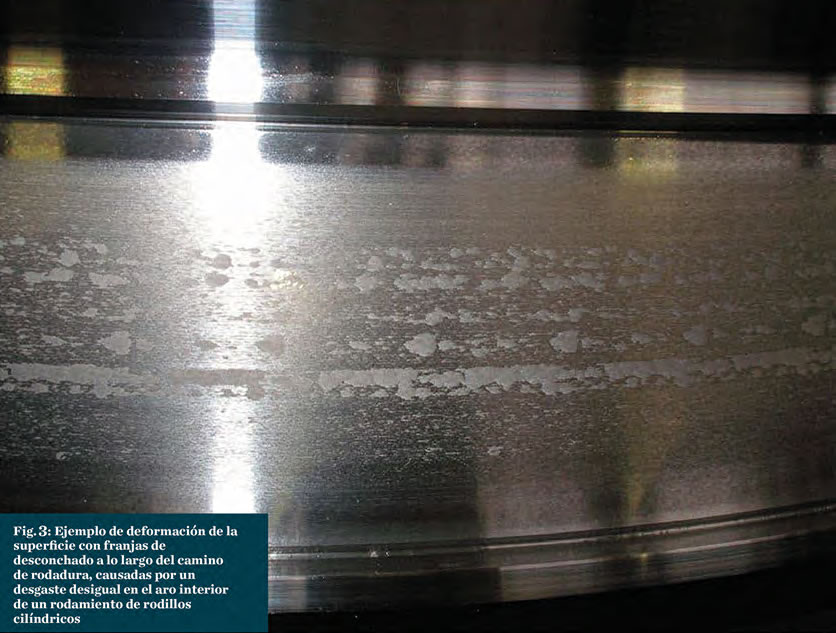

When the bearing problem is lubrication and/or contamination, the consequences that can be observed are damage to the raceways. (fig.1)What are the consequences of this damage? Damaged areas mean that the load is no longer evenly distributed, resulting in localized overloads and an uneven lubrication film. (fig.2). In other words, this damage adds to the original problem and increases the rate at which the bearing deteriorates. A typical consequence is micro spalling or spalling. (fig.3).

This damage can occur in any bearing but, logically, the most exposed are those in applications where contamination or lack of lubrication are more common.

Unfortunately, the complexity of the different parameters involved makes bearing wear unpredictable from a theoretical point of view. This is something that is easily seen when monitoring bearings throughout their service life. That is why SKF has devoted much effort to the investigation of slippage and wear in bearings and the effects on their service life.

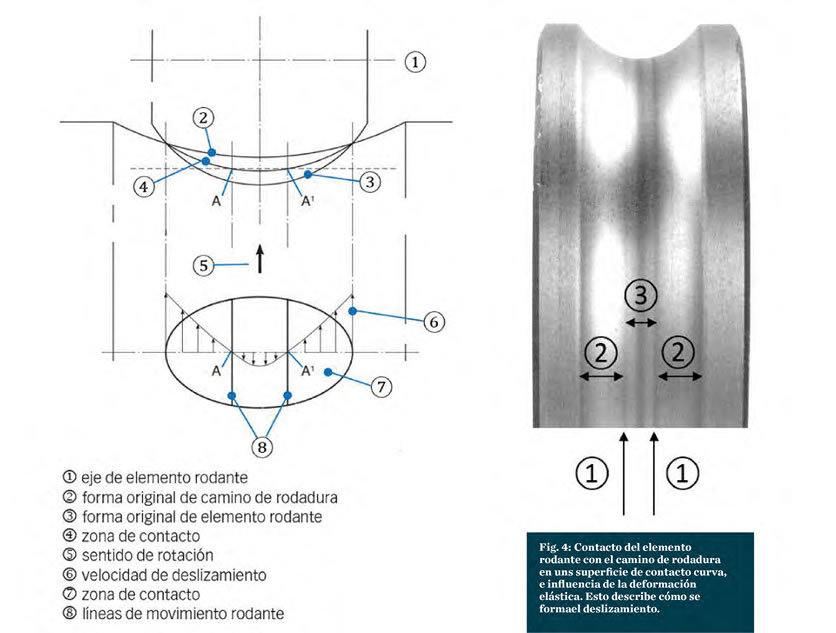

All bearings suffer a certain degree of slippage. It is produced by their internal geometry and load conditions. For example, a perfectly radially loaded radial ball or roller bearing will also have slippage (radial sliding). Heathcote) due to the contact geometry between the rolling element and the hoop and the elastic deformation due to the load (figs. 4a and 4b). Since wear depends on sliding, over time (if the given conditions were correct), it could be expected that the fringes caused purely by rolling (A and A1) would be the only areas where wear would not occur and, therefore, the only ones that would bear the full load on contact.

Fortunately, this would only happen in heavy wear situations while in most cases the bearings are functioning properly. This slippage will be the normal working environment of a trouble-free bearing.

In any case, to avoid wear and tear problems as much as possible, the recommendations from SKF are clear:

- Ensure that the bearing always has adequate lubrication (both in quantity and type). Pay special attention to large bearings with high loads and slow speeds; those that are highly exposed to contamination (especially abrasive contamination); and those that are exposed to corrosion.

- In cases of contamination, reduce it as much as possible. And if it is not possible to eliminate it, use sealing solutions and consider mounting sealed bearings.

- Avoid shock loads and vibrations that cause the bearing to suffer even more.

- In the case of large bearings, if abnormal wear is detected, reconditioning can be a very good solution that also reduces maintenance costs.

If you would like to learn more about bearing wear studies, please visit our article on Rolling Contact Fatiguewritten by researchers from SKF.