There are many reasons why companies in various sectors should have at least one clean room.

Industries such as food, pharmaceuticals or cosmetics, for example, must ensure that their manufacturing processes are spotlessly clean so that no factor contaminates them.

The reasons are clear; the products manufactured or manipulated by organizations in these sectors are consumed by human beings. For that reason, there is no margin for error.

In our entry we will explain the details of a clean room and, in addition, we will show you how to ADALIS can provide you with solutions related to this type of spaces.

What is a clean room?

A clean room is a controlled space in which pollutants are filtered out. such as dust, airborne microbes and aerosol particles, in order to provide the cleanest possible area.

Most cleanrooms are used for the manufacture of products such as electronics, pharmaceuticals and medical equipment.

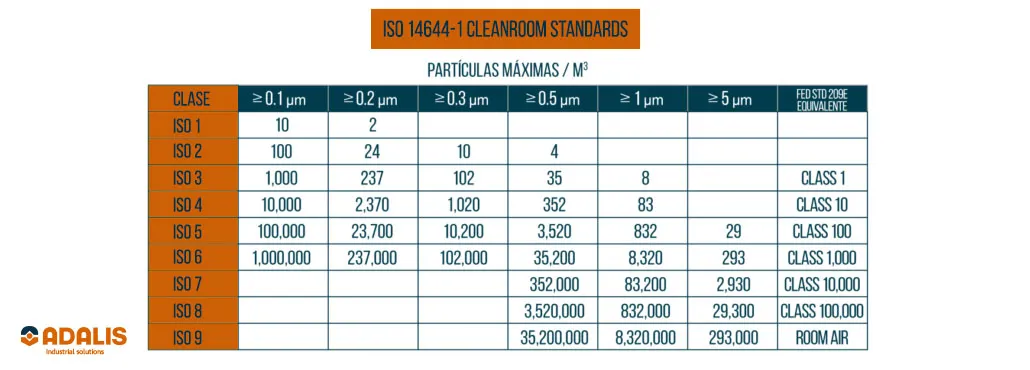

Clean rooms can be classified into different pollution levels depending on the amount of particulate matter allowed in spaceper cubic meter.

These rooms also have devices to control variables such as temperature, air flow and humidity.

How does a clean room work?

The white rooms are conditioned to remove pollutants and particles from the outside air.

The outside air is first circulated to a filter system. Filters (HEPA or ULPA) then clean and decontaminate this outside air to your specifications. The filtered air is then introduced into the cleanroom.

In addition, contaminated air inside the cleanroom is exhausted to the outside through registers, or recirculated back to the filters, and the process is restarted.

Clean room air classification standards

The air classification standards determine how clean the air is inside.

The The formula for determining it is based on the number of particles and their size. per cubic meter in air.

Although there are different classification standards, the most commonly used are:

-

- Federal Standard 209 (FS 209E).

- ISO 14644-1.

Before the International Organization for Standardization (ISO) adopted global cleanroom classifications and standards, the U.S. General Services Administration standards (known as FS209E) were applied virtually everywhere in the world.

FS 209E is expected to be used in some industries over the next five years, but will eventually be replaced internationally by ISO 14644-1.

The FS 209E standard contains six classes, while the ISO 14644-1 classification adds two cleaner and one dirtier class.

A simple way to determine whether it is one system or the other is to understand that FS 209E classes are long numbers such as "class 1,000, class 10,000, ..." and ISO 14644-1 classes are short numbers "ISO 3, ISO 4, ...".

Types of clean rooms according to their ventilation

There are two types of cleanrooms that are classified according to the type of ventilation system they are using.

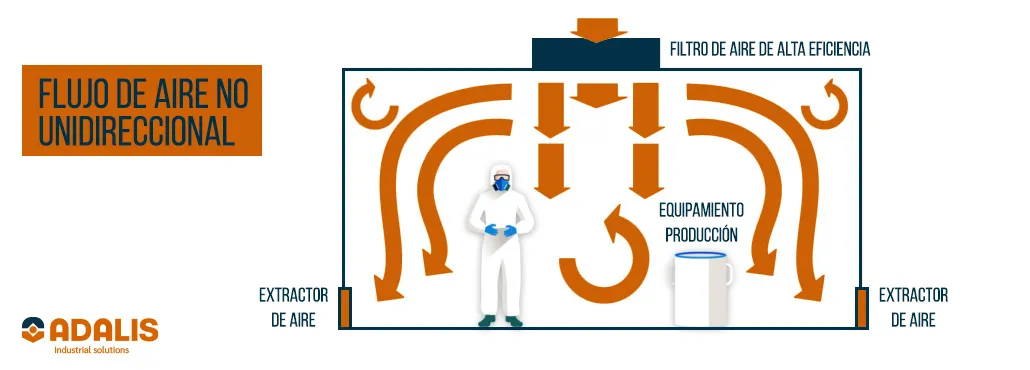

Non-unidirectional air flow

This type of ventilation is commonly referred to as "...".Turbulent ventilation".

Non-unidirectional airflow clean rooms receive clean air filtered through high-efficiency air filters located in the ceiling. The clean air mixes with the room air and removes contamination generated by people and machinery.

The air is exhausted through air extractors located in the lower part of the wall.

With this type of ventilation and depending on the sector and size of the cleanroom, we can achieve ratings up to ISO 6.

Unidirectional air flow

The clean rooms of unidirectional air flow use much more air than clean rooms with non-unidirectional airflow.

The air flow enters through the entire ceiling passing through the filters that are also installed and creates an air flow at a speed between 0.3 m/s and 0.5 m/s eliminating contamination.

The air then exits the room through the floor.

Cleanroom with unidirectional ventilation is more expensive than non-unidirectional, as it can achieve stricter ratings, such as ISO 5 or lower.

ADALIS Industrial Solutions as cleanroom solutions provider

Much of the machinery and cleanroom equipment varies from industry to industry. However, many of them are homogeneous, such as, for example, the clothing.

ADALIS Industrial Solution has a wide range of products that are perfectly suited to the needs of the clean rooms.

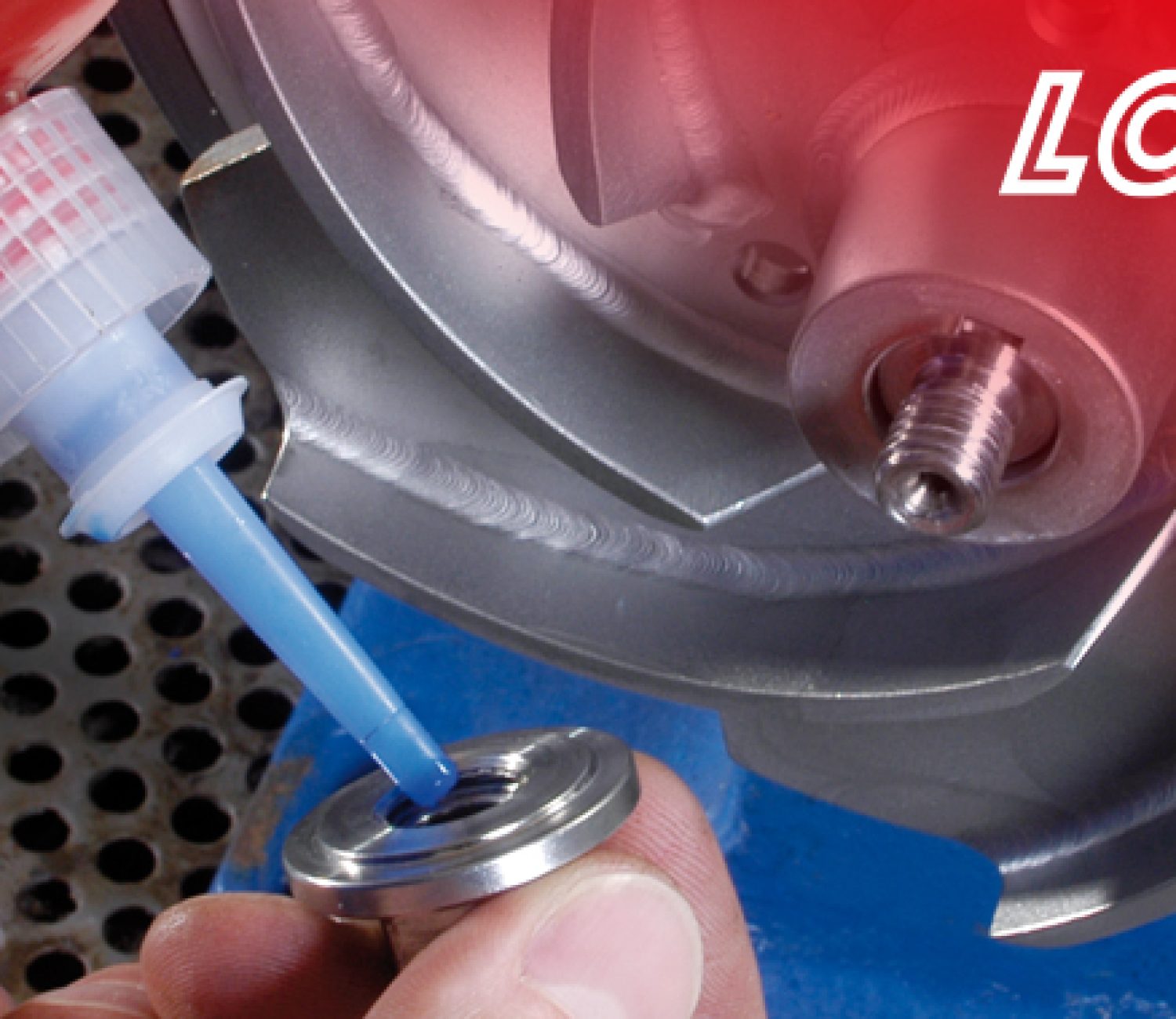

We have stainless steel materials for clean rooms like fittings, valves y PPE from prestigious suppliers such as Festo, Henkel, 3M, Bürkert and Inoxpa, which have the corresponding certifications for these spaces.

Together we can provide a complete cleanroom solution.

We hope this blog has been useful to you. For any related query, contact with our team of subject matter experts.