It is essential to have a good adhesive element to overcome those fastening challenges that we encounter on a daily basis. Today we are going to introduce you to the cyanoacrylate adhesive.

We can't wait to tell you all about this product!

- What is a cyanoacrylate adhesive?

- Applications of cyanoacrylate adhesives

- Bonding and curing time of an adhesive What is the difference?

- When to use an activator and what is it?

- The most complete instant adhesive: Loctite 402

What is a cyanoacrylate adhesive?

In order for you to understand the advantages of cyanoacrylate adhesive we must begin by explaining what it is.

Cyanoacrylate is a colorless liquid with adhesive properties. It is often used as a solution for assembly, do-it-yourself jobs or other spaces in the industrial sector, but it is also frequently used at home.

Cyanoacrylate is more commonly referred to as instant adhesivereferring to its short fixation speed when joining two objects.

It usually dries at room temperature and, due to its characteristics, is usually used for very fast, high-performance joints. This is because these adhesives are single-component and are stabilized in acidic media. Thus, they react quickly at room temperature when in contact with moisture.

Application of cyanoacrylate adhesive

Cyanoacrylate adhesive is ideal for bonding pieces of different materials; rubber, plastic, wood, porcelain, metal..., to each other. It is a perfect solution for joining small and medium sized componentsalthough he also dares to take on some larger projects.

In order to adhere one element to another, it is essential that both sides to be bonded are properly treated and cleanedThe adhesive can perform its effect in the best possible way. In our blog we explain in detail how to prepare the faces to carry out the bonding of two objects.

Next, it is necessary to put a adequate amount of productneither too much nor too little.

Excess product will protrude from the surface of the bonded space and a lack of product may cause the element to eventually separate.

Cyanoacrylate adhesives have the capacity to to be fixed very quicklyThe joint will be fixed in just a few seconds.

Setting and curing time of a cyanoacrylate adhesive What is the difference?

When we talk about cyanoacrylate adhesives we emphasize as a main feature the instant fixation time it has, but not its curing time, what do we mean by this? What is the difference?

The difference between setting time and curing time lies in the following factors the concept itself.

The adhesive setting time is considered to be the time lapse between the moment the product is applied and the moment the bond is strong enough to handle without compromising adhesion. Thus, in cyanoacrylate adhesives, bonding is seconds.

For its part, the curing of adhesives instantaneous curing times can be as long as 24 hours. This is because the curing time is the period between the time the product is applied and the product reaches its highest strength.

What can we do to also increase the speed of curing? Use an adhesive activator.

What is and when should an adhesive activator be used?

An instant adhesive activator is an instant adhesive activator.should be used before or after the application of the cyanoacrylate product to perform a acceleration of curing speed.

They can be used to increase gap filling capability They are also very useful when fixing an element in a specific space, for example, a cable.

An example of a product activator is the Loctite SF 7455can be used before and after the adhesive to improve its curing speed.

The most complete cyanoacrylate adhesive: Loctite 402

Now that we have already told you about cyanoacrylate adhesives, we want to show you one of Loctite's new products, the Loctite 402.

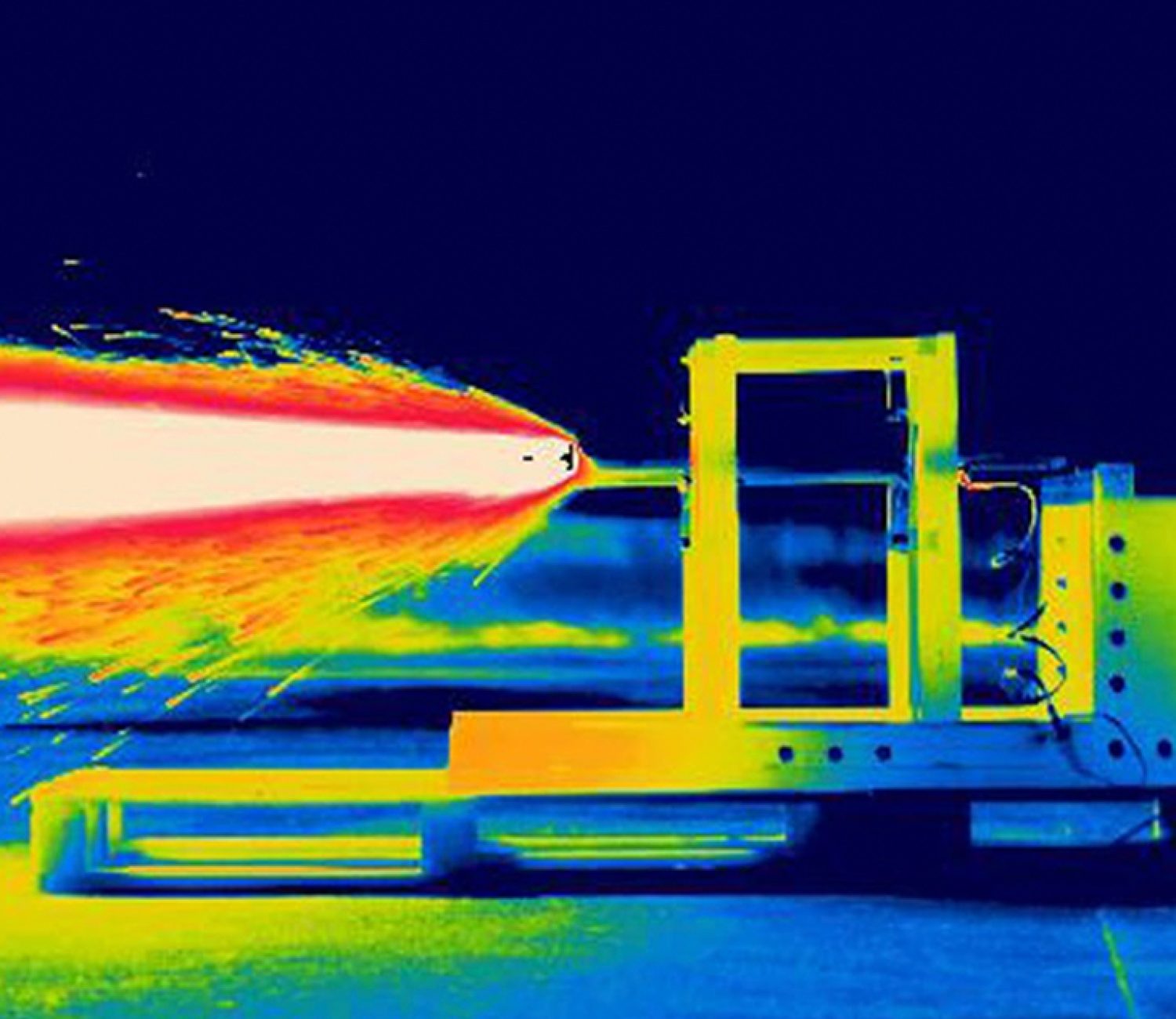

The new Loctite 402provides a very high heat resistance up to 135ºC.

Among the new features it presents, we find its capacity of creating high-strength joints on a wide range of materials, even those with difficult adhesion.

Its exclusive patented formula minimizes hazardous components that any adhesive of this caliber can have.

In the case of steel, it has been shown to have a speed of 20 seconds of fixation.

The Loctite 402 has been formulated and tested with extreme conditions and the results have been clear; a highly reliable performance.

Outstanding features

- The Loctite 402 has a viscosity of 110 mPa.s (cP) and can fill clearances of up to 0.15 mm.

- It is also noteworthy for its cut tolerance from 15 N/mm2.

- This adhesive model Loctite 402has been designed to give maximum resistance to the maximum number of possible substrates, whether metal, rubber, wood, cardboard, ceramics and plastics.

- It has the ability to withstand thermal aging up to 135ºC and -40ºC, a very interesting advantage for the industrial sector. In addition, its formula is free of hydroquinone.

We hope we helped you!

If you need us to answer any questions about this blog post, please contact us at contact with us.