In industrial work environments where exposure to particles, gases or chemical vapors is high, protecting the respiratory tract of workers with PPE masks is a priority.

At Adalis we are specialists in respiratory protection. Therefore, we manage both self-filtering and reusable respirators. On this occasion, we will focus on the latter.

Our approach goes beyond being company supplying reusable facemaskswe offer a integral industrial maintenance service, The company's technical expertise, regulatory screening, inventory management and usage control combine to ensure a safe and efficient environment.

What are reusable face masks and when should they be used?

Reusable respirators are respiratory protection equipment designed for industrial environments with chemical, biological or physical hazards. They are the PPE that help us to protect ourselves in certain jobs and sectors. And their advantage, as opposed to disposable masks, is the higher degree of protection against external factors, the possibility of replacing their filters, cost optimization and environmental sustainability.

When to use reusable PPE masks?

To determine the need for the use of an EPI mask, the following steps should be followed:

- Know the type of hazard

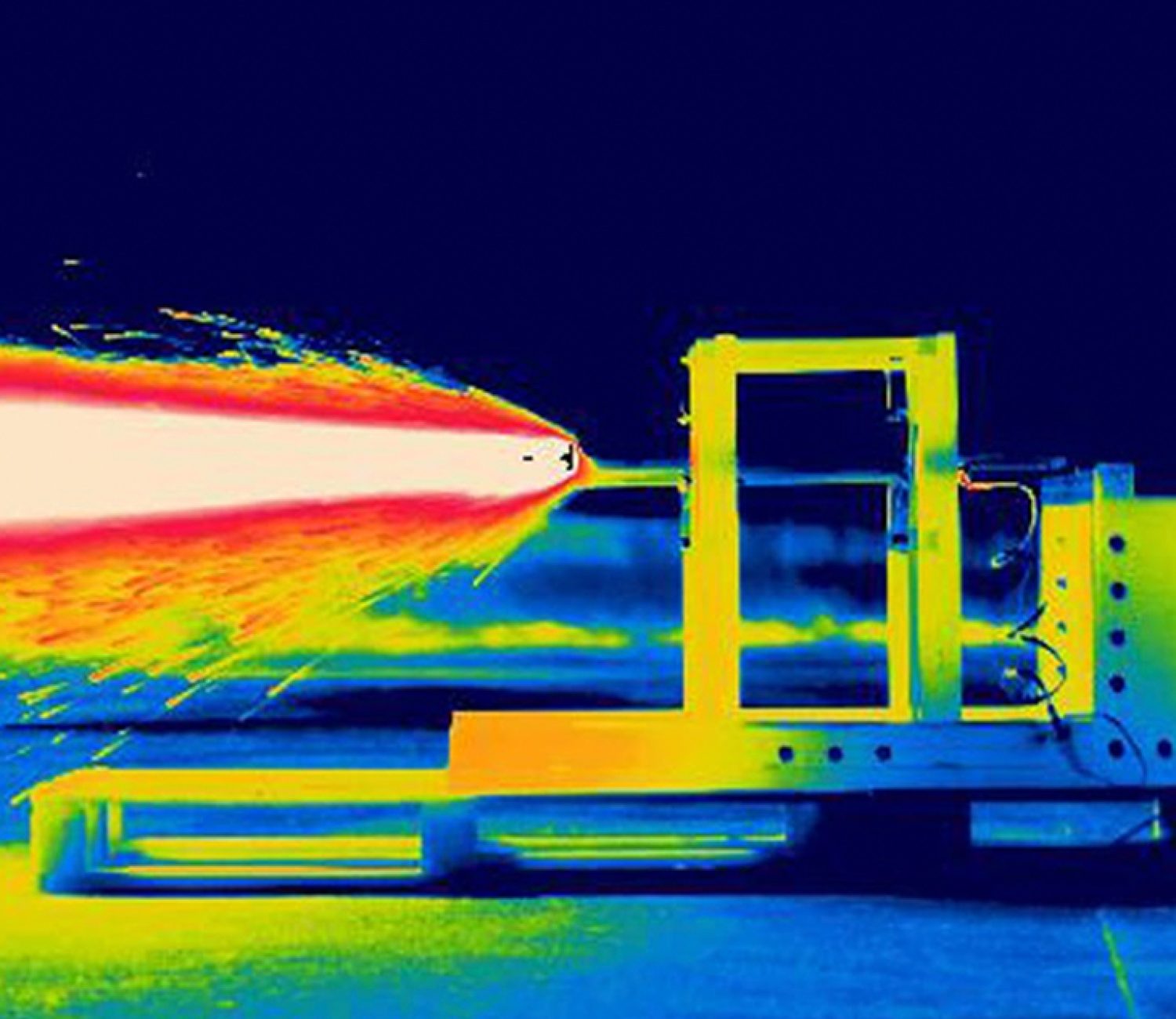

The first step is to know the work environment and assess whether it contains a risk of particulate matter such as:

- Solid particles: dust, fibers or aerosols.

- Gases and vapors: solvents, chlorine, volatile chemical compounds.

- Combined risk: simultaneous exposure to particles and gases.

- Assess whether respiratory protection is necessary

The second step will be the evaluation of the exposure levels according to the analyzed substances. The results are calculated according to the:

- Measurement, in PPM or mg/m³.

- Comparison with occupational exposure limits according to European regulations.

If these levels are higher than those permitted by the Occupational Safety and Health Administration (OSHA), the use of respiratory protection is obviously mandatory. But if the levels do not exceed the exposure limits for chemical or physical substances, the use of EPI masks is also recommended as a protective measure.

- Determine the level of protection

The third step is to determine the level of protection factor required, depending on the job.

The NPPF or Nominal Protection Factor is the ratio between the concentration of a contaminant in the ambient air and the concentration of the same contaminant in the inhaled air inside a respirator. The formula for calculating the Nominal Protection Factor (NPF) is as follows:

FPN = Ambient Concentration / Inhaled Concentration

For example, half-mask respirators with filters and cartridges have an assigned protection factor of 10.

- Choosing the right type of respirator

The fourth and final step, once the protection factor has been determined, is to select reusable masks according to the workplace.

Another element to take into account, in addition to the environment and the hazard, is the comfort of the respirator depending on the workplace: there are jobs that prove to be very strenuous, so lighter and more aerodynamic reusable masks will undoubtedly be better or more comfortable in continuous use.

Types of reusable face masks and technical applications

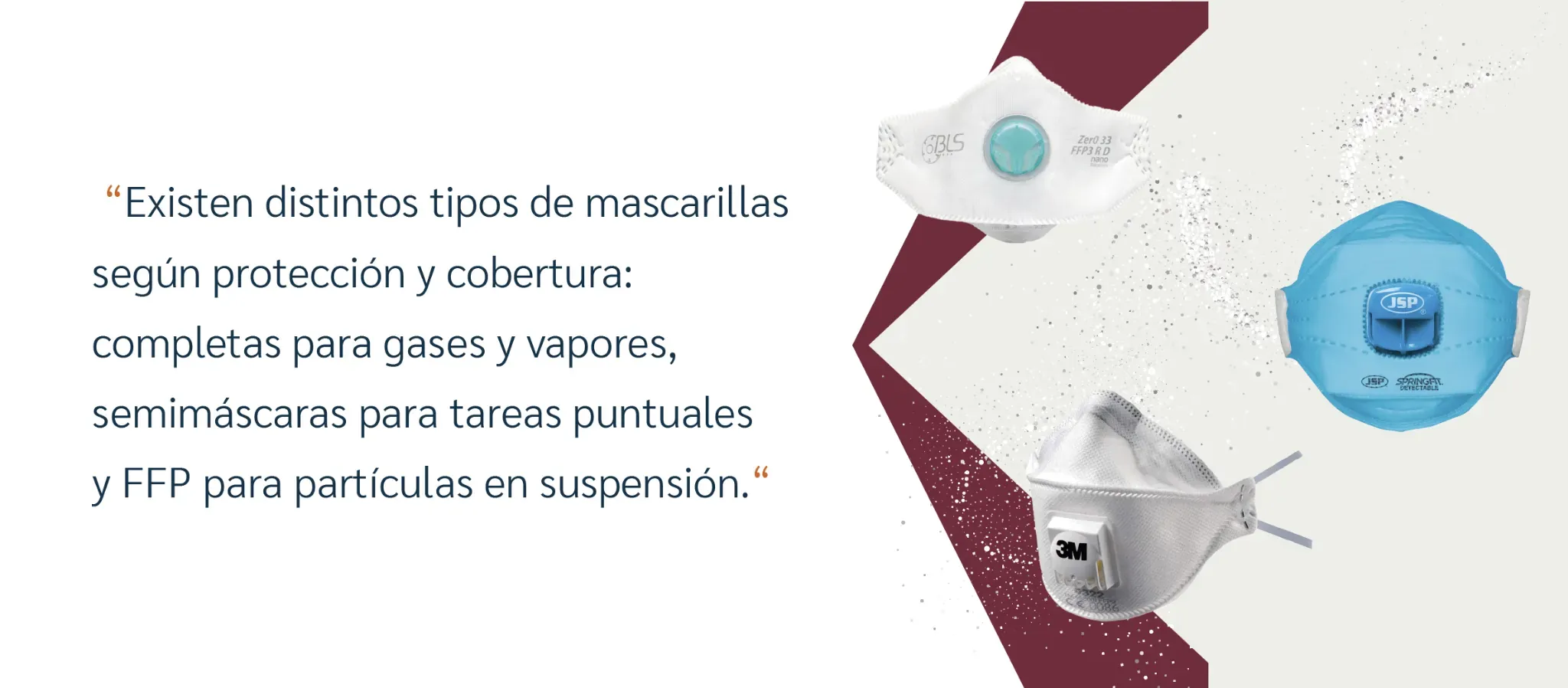

At Adalis, we classify masks according to the level of protection and the area of coverage:

Complete PPE masks

Full face masks are those that cover eyes, nose, mouth and chin. They are masks for protection against noxious gases and vapors and can be fitted with different interchangeable filters. Complete PPE also have the option of integration with air supply systems.

Half masks or half masks

Half masks are those PPE equipment that cover the nose and mouth. Available with one or two filters (also known as single and double pattern masks), half masks are suitable for specific tasks of short or medium duration.

Reusable self-filtering respirators FFP3

The industrial protective masks protect the worker from the inhalation of hazardous substances and particles in suspension. The main characteristic of this type of self-filtering masks, or disposable masks, is that they are the simplest PPE respiratory protection equipment.

These FFP3 masks protect against the risks produced by inhalation of environmental contaminants, but not against vapors or gases.

Mask advisors and suppliers for each job position

Adequate reusable respirators and an efficient management system are key to protecting workers and maintaining operational continuity.

Our services combine technical advice, constant product availability and control of use, ensuring that each workstation has the necessary protection at all times. The main benefits of these solutions are:

At the technical level:

- Specialized advice on the technical evaluation of the job.

- Recommendation of the type of reusable mask appropriate to the risk.

- Replenishment service that guarantees continuous product availability.

- Control of the use and status of each mask, managed through the Inventory Management System (IMS) of Adalis.

At an economic and efficiency level:

- Avoid unexpected downtime due to lack of stock.

- Cost reduction by not tying up inventory; stock is managed on Adalis IMS machines.

At the safety, quality and compliance level

- Certified and selected products from top brand suppliers, ensuring compliance with applicable regulations.

Intelligent management of masks and PPE with Adalis IMS

To ensure that reusable respirators and other PPE are always available, in good condition and properly managed, we integrate respiratory solutions with IMS (Inventory Management Solutions), our inventory management system. management of fast-moving products. This model allows real-time stock control, automates replenishment and ensures traceability in the use of each piece of equipment.

Depending on the needs of each plant, we have different IMS solutions available: individualized control of withdrawals and automatic replenishment, updated inventory without the need for immobilized stock or monitoring of PPE status, expiry dates and replacement alerts.

With Adalis, the management of reusable respirators and inventory control of filters and other PPE is no longer a concern. Our comprehensive approach allows your team to work protected, complying with PPE regulations and optimizing plant operations without interruptions due to lack of stock.

Find out how our PPE consulting and management services can improve your company's safety and efficiency: contact us today. contact with Adalis today.