Did you know that the wear resistance of a chain is fundamentally related to lubrication?

Drive chains are the ideal choice for applications that transmit high torque and where the drive shafts move in the medium to low speed range.

We are talking about robust transmissions, which allow working in adverse environmental conditions and high temperatures; where lubrication is essential to achieve a long chain life. At ADALIS Industrial Solutions provides you with the best lubricants which, together with a regular maintenance program, will optimize the performance of the drive train to the maximum.

The drive chains provide a fixed transmission ratio between the speeds and angle of rotation of the input and output shafts, which allows their application in automotive and general machinery that requires it.

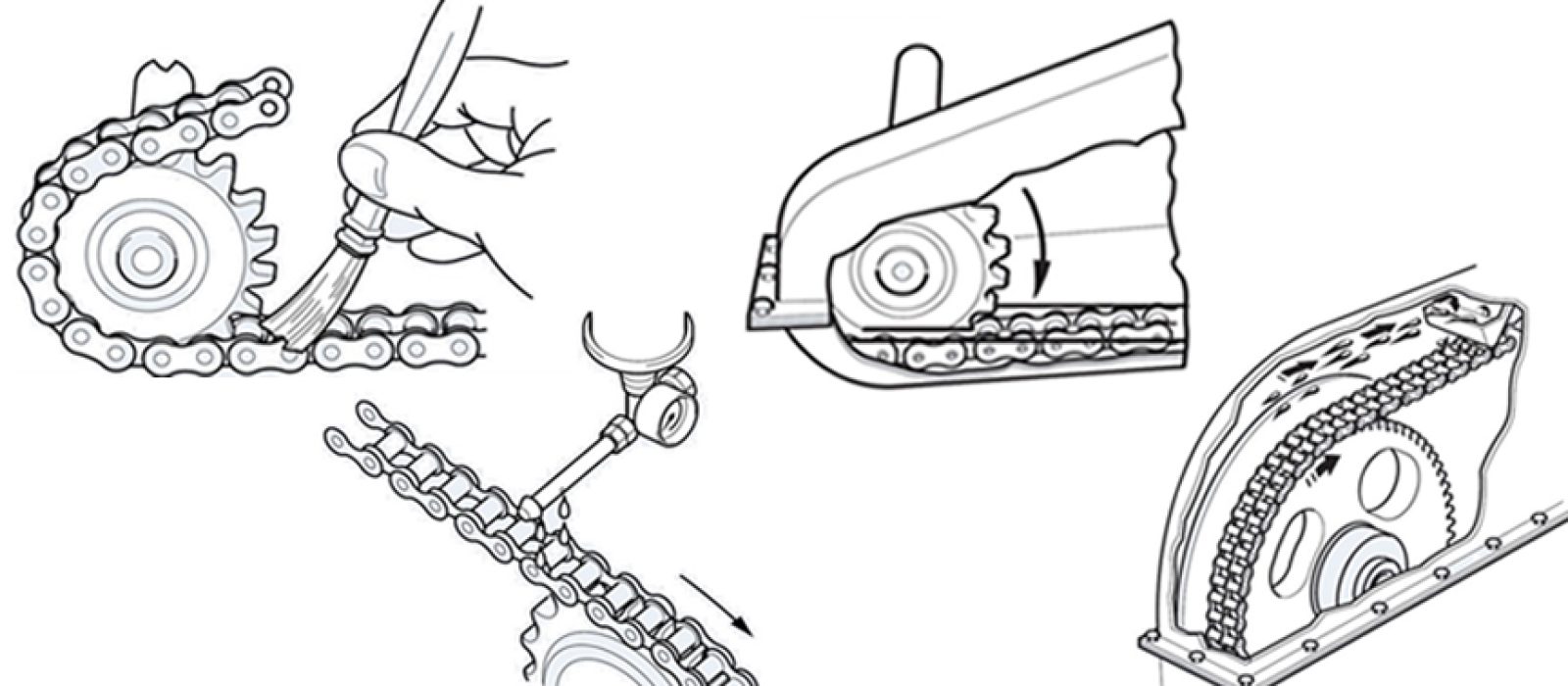

As the chain passes through the wheels, the relative movements between pins and bushings cause wear on the joints, resulting in slack and unnecessary chain elongation, which slows productivity.

Defective lubrication results in irregular wear, which can be caused by a momentary shortage of lubricant, by the use of a low-quality lubricant, by excessive dirt in the lubricant or by the use of an unsuitable viscosity grade. What problems can be encountered:

-

- Low lubrication

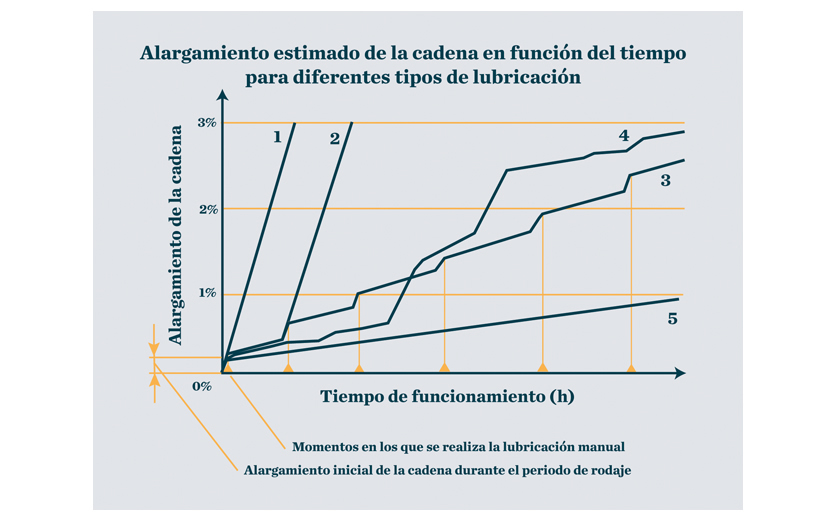

In a situation where the chain is never lubricated, dry running causes accelerated wear with the time the chain is in use.

-

- Single lubrication

If we opt for a single lubrication, we will delay accelerated wear for a certain period of time, but it will eventually survive and reappear sooner or later.

-

- Manual lubrication

This type of lubrication causes saw-tooth wear, as wear is reduced when lubrication is applied and increases sharply when lubrication is lost (which is when lubrication renewal is required).

We cannot ignore the fact that wear is one of the main and most lethal enemies of the drive chain. Only periodic maintenance and the use of the best lubricants will mitigate its effects, providing a healthy and productive life to the chain.

Optimum lubrication delays wear elongation, maximizing chain life.

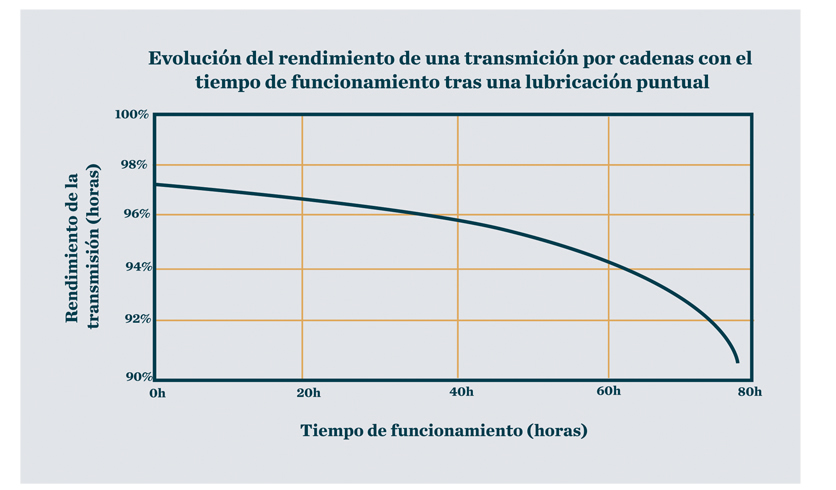

Lubrication not only influences chain wear and elongation, but also transmission performance.

In a chain transmission, optimal lubrication is essential for the functions it performs:

-

- Lubrication

This is undoubtedly the main function. It tries to avoid metal-to-metal contact that could occur between the moving parts of the chain by forming a lubricating film.

-

- Cooling

The heat generated due to friction can seriously affect the life of the metal parts that make up the chain.

In high temperature or extreme speed applications, a lubricant cooling system is usually installed to increase the heat dissipation capacity of the lubricant.

-

- Cleaning

In drive chains, there are numerous metal parts pressed against each other, which means that any particle that enters the system can cause significant abrasion. Cleanliness is fundamental and lubricant is essential in this function. In cases of extreme dirt, the lubricant must be conveyed through a filter that removes particles from the circuit.

-

- Cushioning

The film of lubricant inserted between the load-carrying parts along the chain provides a flexible cushion capable of cushioning, to some extent, the shock loads that occur during transmission operation.

From ADALIS Industrial Soltions we can offer you advice on the design of periodic maintenance routines, as well as on the best lubricants available for each application. We will take into account the requirements of speed, temperature, work, etc., of each point of application to offer you with guarantees of long life to your production line.

We have the best products for greasing and lubrication of machinery. Contact us at here.