In all types of work it is necessary to comply with certain requirements when talking about occupational risk prevention. This is even more important when we talk about classified areas. ATEX (with risk of explosion). In these environments, hand tools are no exception and have to comply with certain safety standards in order not to represent a risk. One of the most common risks, talking about tools, is ignition by friction and to avoid it, tools such as ATEX anti-spark tools are used..

This type of risk can occur especially in environments where there is the possibility of free combustible gases. The contact of two metals can generate a spark and trigger an explosion. For this reason, anti-spark tools are used in petrochemical companies, munitions plants, electrical companies and fuel or flammable material warehouses.

What are these tools made of?

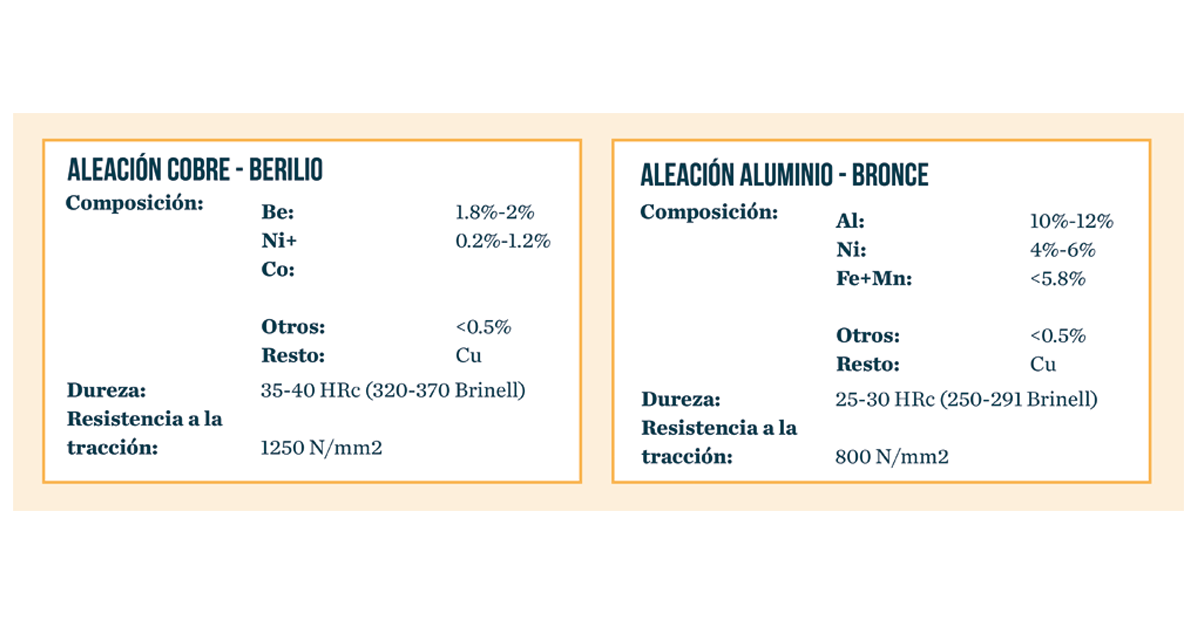

The most common materials used for the manufacture of these tools are non-ferrous alloys, such as bronze and the copper. Bronze is the most common choice (by price) mixed with aluminum, but that does not mean that it is always the most appropriate.

Copperin alloy with materials such as beryllium, nickel and cobalt, is the ideal material for the manufacture of non-sparking tools.. Even though it has a higher cost, its greater hardness represents an added value, and sometimes the increase in durability compensates for the higher purchase cost.

It is important to note that the anti-spark toolThe non-steel tool will wear more quickly depending on the working environment, the care given to it and the quality of the manufacturing material. Anti-spark tools also have anti-corrosion properties for use in harsh working environments.

Where to use the anti-spark tools?

Where to use the anti-spark tools?

The anti-spark tools are to be used in work environments where there may be a risk of explosive atmosphereswhere a spark due to friction can cause an explosion.

The ATEX Directive warns us about the type of equipment suitable for explosive atmospheres, depending on the level of risk presented by the environment.

The tools are considered spark-proof and comply with the ATEX directive for use in zones:

0, 1 and 2: Explosive atmosphere by gas and vapor.

20, 21 and 22: Explosive atmosphere due to dust cloud.

How to keep anti-spark tools in good condition.

The anti-spark tools are not as strong as the steel ones, so it is very important to make a comprehensive maintenance in order to extend its life.

For this purpose, it is highly recommended to take the following considerations into account:

- Keep tools clean: Avoid contact with corrosive products that may affect the properties of its materials. Once the anti-spark tool has been used, it must be cleaned to avoid its deterioration.

- Do not use in environments with acetylene: Acetylene, in high temperature or humid environments, can cause the formation of explosive acetylides when it comes in contact with the tool, this can cause a considerable explosive environment.

- Periodic reviews: Wear-prone non-sparking tools such as hammers, punches, etc., should be checked frequently.

Little by little, all companies belonging to potentially hazardous sectors such as gas production plants, petrochemical plants, pharmaceutical industries, mining as well as airports, hazardous material warehouses, nautical sector, etc. have understood the importance of having anti-spark tools in all their maintenance departments, in order to avoid accidents that put human life at risk.

For the distribution of this type of tools Epidor TD has relied on a leading brand in the sector, such as Egamasterwhich has been working and innovating in the area of anti-spark tools for years.

We strongly believe in our employees and work to maintain the safety of all our customers.