In EPIDOR Technical Distribution we have a wide catalog dedicated to all types of industrial material. Among our offer stands out the range of sliding and friction elements that, thanks to the wide possibilities of materials and performance, offer all kinds of solutions to the needs of our customers.

Our preferred supplier Glacier Garlock Bearings (GGB) designs and manufactures sliding bearings in multiple shapes and materials, which makes it a world leader in this type of elements with presence in sectors such as automotive, railroad, power generation, aerospace industry as well as in multiple industrial applications in general.

Therefore, we would like to share their extensive knowledge through a brief introduction to the vast and attractive world of plain bearings.

The use of bearings, however simple, dates back at least as far as the ancient Egyptians, and perhaps even predates the invention of the wheel. Today's bearings can be found wherever there are two surfaces in contact and relative motion, which includes virtually all types of machinery, from household appliances to industrial equipment.

WHAT IS A BEARING?

Bearings are tribological components that carry a load while in mutual contact with another body and exhibit relative motion to each other. The motion can be sliding or rotary.

There are basically two different types of bearings: sliding bearings and rolling element bearings. Other types include hydrodynamic bearings, which support their loads on a thin layer of liquid or gas; magnetic bearings, which use magnetic fields to carry their loads; bending bearings, in which the load is supported by a folded element; and high-precision bearings, used in watchmaking.

SLIDE BEARINGS

Slide bearings - also known as bushings, bushings, plain bearings or plain bearings - are generally cylindrical in shape and contain no moving parts.

Slide bearings - also known as bushings, bushings, plain bearings or plain bearings - are generally cylindrical in shape and contain no moving parts.

Standard configurations include cylindrical bushings, flange bearings for radial loads and light axial loads, thrust washers and cylindrical bushings for radial loads, flanged thrust washers for heavy axial loads and sliding plates of various shapes. Custom designs are also possible, including special shapes, sizes and features (grooves, cavities, notches, flanges, etc.).

Plain bearings are used for sliding, rotary, oscillating or reciprocating motions. In sliding applications they serve as sliding bearings, sliding rails and wear plates. In these applications, the sliding surfaces are generally flat but can also be cylindrical, and the motion is always linear rather than rotary. Rotary applications consist of cylindrical surfaces and the motion can consist of unidirectional or bidirectional displacement. In reciprocating and oscillating applications, the surfaces are flat or cylindrical, but the displacement is bidirectional.

Slide bearings can be manufactured in one solid piece or, for ease of installation, open with a longitudinal groove (rolled sheet bushings). It is important that the bearing is selected according to a given application. High loads require bearings with larger contact area and high load capacity. Bearings with solid lubricants are designed to operate at higher temperatures than bushings lubricated with oil or grease. And high-speed applications require special lubricants to minimize heat and friction buildup.

Slide bearings are manufactured in various designs and product selection depends on the operating conditions of the application and performance requirements.

A WIDE VARIETY OF BEARING MATERIALS

The metal-polymer bearings consist of a metal support, usually steel or bronze, on which a porous bronze layer is sintered and then impregnated with a PTFE coating and additives to obtain a sliding layer resistant to friction and wear. These bearings can operate dry or with external lubrication.

The metal-polymer bearings consist of a metal support, usually steel or bronze, on which a porous bronze layer is sintered and then impregnated with a PTFE coating and additives to obtain a sliding layer resistant to friction and wear. These bearings can operate dry or with external lubrication.

Sliding bearings can also be manufactured with high-performance thermoplastic materialsThe bearings provide excellent wear resistance and low friction under both dry and lubricated operating conditions. Thanks to an injection molding process, thermoplastic bearings can be designed in virtually any shape and are made from a series of resins compounded with filler materials and solid lubricants. They have excellent dimensional stability, low coefficient of friction and good thermal conductivity.

Sliding bearings can also be manufactured with high-performance thermoplastic materialsThe bearings provide excellent wear resistance and low friction under both dry and lubricated operating conditions. Thanks to an injection molding process, thermoplastic bearings can be designed in virtually any shape and are made from a series of resins compounded with filler materials and solid lubricants. They have excellent dimensional stability, low coefficient of friction and good thermal conductivity.

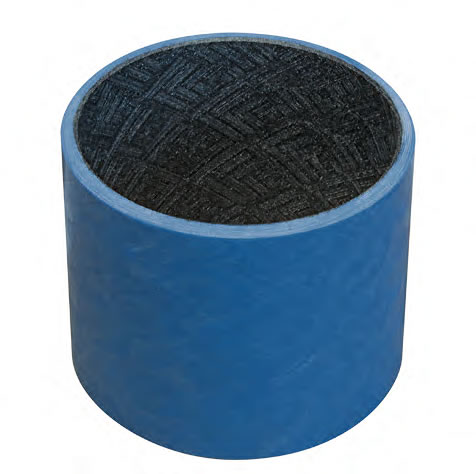

The fiber-reinforced composite bearings are another type of sliding bearings that consist of an epoxy base layer impregnated with continuous filament glass fiber with various low-friction wear-resistant bearing liners. This structure allows the bearings to withstand high static and dynamic loads, while their inert nature makes them ideal for corrosive environments.

The fiber-reinforced composite bearings are another type of sliding bearings that consist of an epoxy base layer impregnated with continuous filament glass fiber with various low-friction wear-resistant bearing liners. This structure allows the bearings to withstand high static and dynamic loads, while their inert nature makes them ideal for corrosive environments.

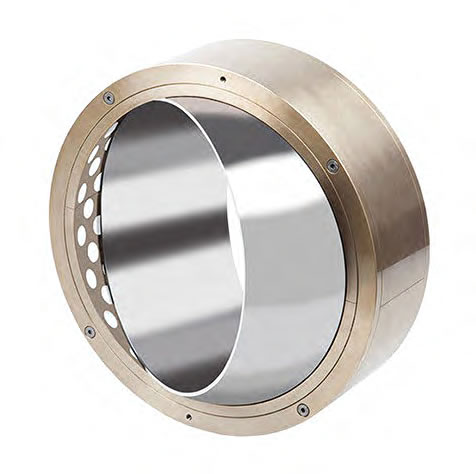

The monometallic, bi-metallic and sintered bronze bearings are designed for use in applications with high loads and low speed movements, whether for land or underwater industrial applications. The solid bronze bearings impregnated with lubricant offer maintenance-free operation in high-temperature applications, while monometallic and bimetallic bearings are designed for lubricated applications.

The monometallic, bi-metallic and sintered bronze bearings are designed for use in applications with high loads and low speed movements, whether for land or underwater industrial applications. The solid bronze bearings impregnated with lubricant offer maintenance-free operation in high-temperature applications, while monometallic and bimetallic bearings are designed for lubricated applications.

With GGB bearings, you can achieve longer service life at all your friction points. If you want to consult all the articles we distribute corresponding to this range of products, you can do it here.