A few months ago we told you about an association with which we have been collaborating for some time, Cosmic Research. With them we are united by the desire to help progress a group of students who pursue a great common dream, to be the first students to send a rocket into space with their own design and manufacture.

Fact or fiction?

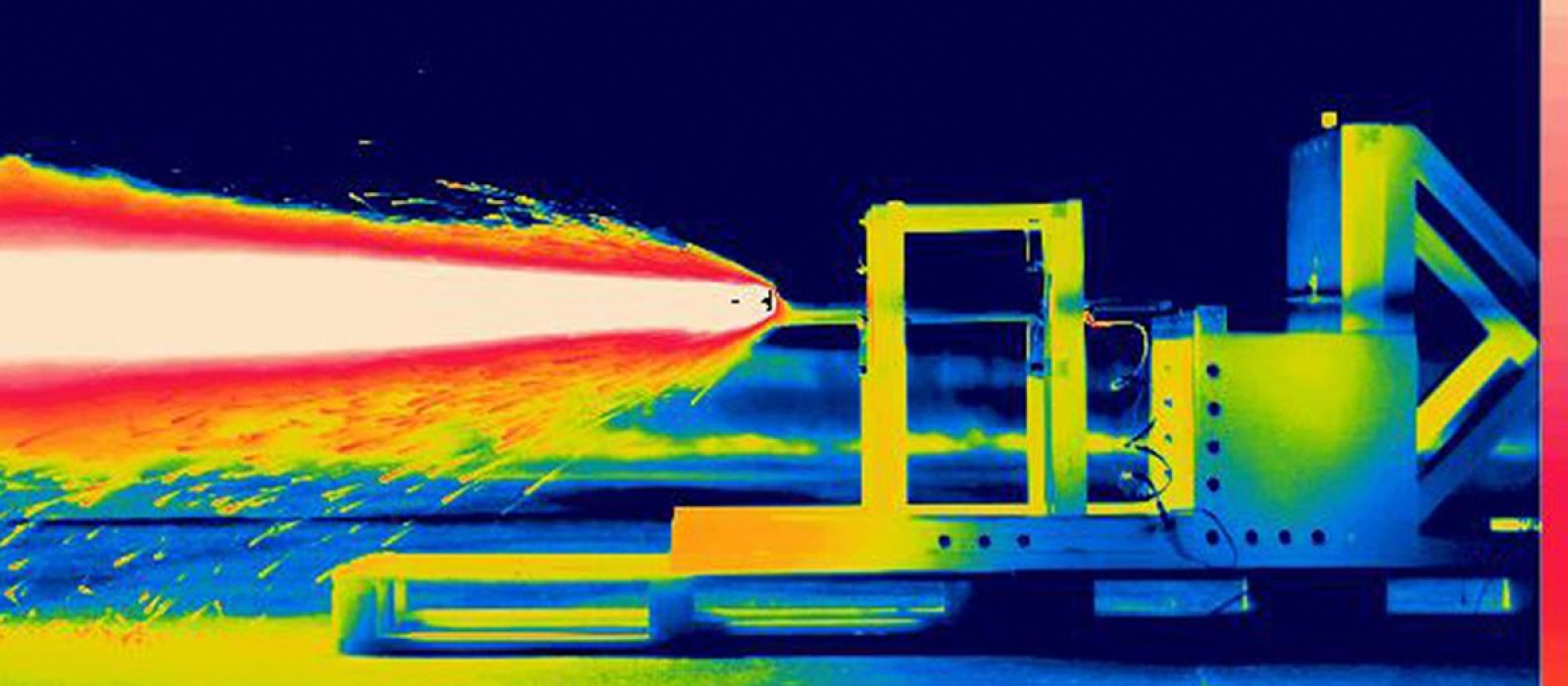

After many hours of work, last March 2 and 16 they carried out some tests at the Alguaire airport (Lleida), which has helped them to start with the final design of what will be the definitive rocket engine. This test has been a turning point in the project, helping them to take into account many factors that they had not considered until now.

For the tests, they used gaskets that our technical department recommended. These are novaform® SK flat gasketsThe flat gaskets were used to seal the engine combustion chamber, the ignition system and to protect key elements of the prototype. As they are flat gaskets, their assembly was simpler, without taking up so much space and thus making the design lighter.

The novaform® SK material is prepared to withstand extreme temperatures, offering high mechanical performance. On the other hand, aramid fibers reinforced with a steel mesh allow these possibilities, being able to work from -100 ºC to 600 ºC. A temperature range that very few materials allow.

The tests were a great success. success!

The students were able to ensure that no leakage occurred and that the threads were completely protected. In the coming months, Cosmic Research will continue to carry out tests, and ADALIS Industrial Solutions will be at their side at all times. We will keep you informed of this project, which is moving further and further away from fiction and closer to reality!